What Safety Precautions Are Taken During the Installation of A Passenger Lift?

The installation of a ascensor de pasajeros is a complicated process, with many safety precautions taken.

First, all workers must wear safety goggles and gloves at all times. They must also wear steel-toed boots specifically designed for working in high-risk environments. Workers must also wear an appropriate respirator mask while cutting through the building floor. In addition, there should be at least two people present during any demolition or construction work; one person to operate the jackhammer and another to ensure that no one is standing in the area being worked on by the jackhammer.

The most crucial safety precautions include making sure that there is enough light in the area where work is being done so that everyone can see what they are doing clearly; making sure that everyone knows where all electrical outlets are located so that they do not accidentally hit one when operating equipment such as a jackhammer; keeping everyone clear from any areas where debris may fall from above (such as from above elevators); making sure that everyone knows how to operate machinery used for heavy lifting (such as forklifts), and ensuring that all employees know exactly what their role is during each phase of construction or demolition work so that confusion about who is who doesn’t lead to unnecessary accidents.

Are There Particular Requirements for The Size and Weight of A Passenger Lift?

The size and weight of a ascensor de pasajeros are regulated by the American Society of Mechanical Engineers (ASME). The ASME B30.1-19 standard provides guidelines for the design, installation, and operation of elevators and escalators. The ASME code states that passenger lifts must be designed to accommodate the maximum rated load, determined by the number of passengers and their weight.

The maximum rated load for a passenger lift is based on the following:

-NUMBER OF PASSENGERS: The number of passengers should not exceed 15 times the number of cars in the passenger lift. For example, if there are 4 cars in a passenger lift, the total number of passengers should be 60 or fewer. This is due to safety reasons; if too many people were riding at once, it could cause problems with overloading or stress on parts like cables and pulleys that would lead to mechanical failure over time.

What Materials Are Needed to Complete A Passenger Lift Installation Successfully?

The answer depends on the characteristics of the building and the lift.

For example, a straight-up lift may require different materials than a curved one. The type of building also matters: A modern building will need different equipment than an older building.

The materials needed for installation include:

- A hoist or platform that can support up to 750 pounds and can be raised at least 20 feet high without compromising safety

- An elevator shaft with an opening large enough to accommodate your lift

- An electrical outlet in the shaft with enough power to run the lift’s motor

Can I Trust The Quality of A Professionally Installed Passenger Lift?

Yes, you can trust the quality of a professionally installed passenger lift.

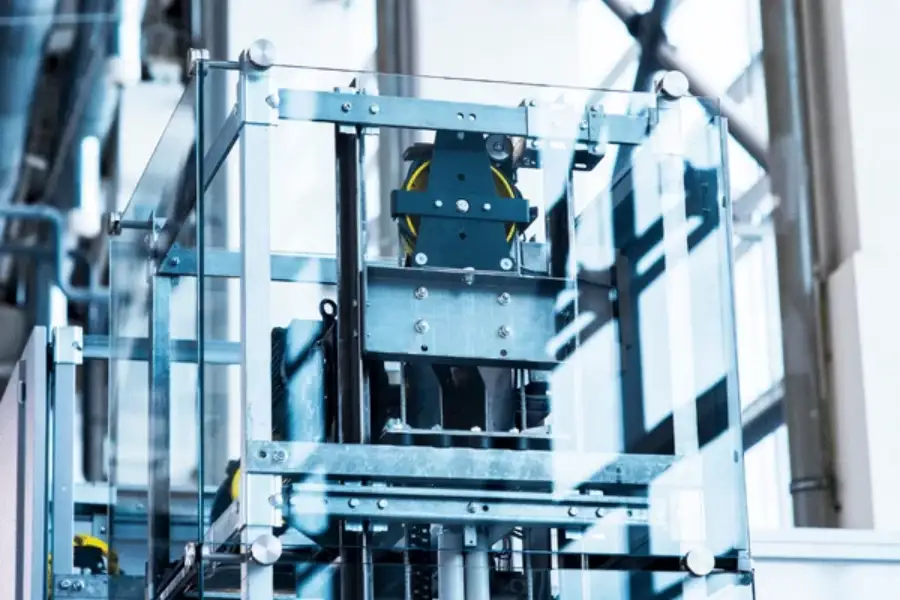

ascensores de pasajeros are designed to carry people from one floor to another. An electric motor drives the lifts, which are governed by an automatic control system that ensures safe operation. The lift is typically equipped with safety devices, such as a limit switch and a safety brake, designed to stop the lift if something goes wrong.

A professionally installed passenger lift will have undergone rigorous testing to ensure it meets all applicable standards and regulations. These tests include:

- Safety inspection

- Structural inspection

- Functional inspection

- Power source inspection

How Long Does It Typically Take to Install A New Passenger Lift?

In most cases, a new ascensor de pasajeros can be installed within a few days. If the lift is being installed in an existing building, it may take longer as the work area must be prepared, and the building must be closed off from public access while work is being done.

In addition, other factors can affect how long it takes to install a new passenger lift. For example, if the building has not been built to code or if there are other structural issues (such as narrow doors), this will increase the amount of time required for installation.

Are Any Professional Qualifications Necessary to Install A Passenger Lift Legally?

The short answer is “yes,” though there are some exceptions.

The Americans with Disabilities Act (ADA) requires all passenger lifts to be installed and maintained by a qualified professional. The ADA stipulates that this professional must have expertise in the installation and maintenance of passenger lifts, as well as familiarity with fire safety codes and other regulations specific to elevators.

The ADA also provides exceptions for certain types of businesses and situations:

- Small businesses with fewer than 15 employees may be exempt from hiring a qualified professional if all of their employees have completed an online course on elevator safety standards.

- Small businesses may also be exempt if they have no more than 2 passenger elevators in operation at any given time and only install or maintain those 2 elevators themselves; however, this exemption does not apply if those same small businesses install or maintain any other type of elevator outside of those 2 passenger elevators.

Is It Possible to Install an Existing, Used Passenger Lift?

Yes, it is possible to install an existing, used ascensor de pasajeros. However, some essential considerations must be considered when installing a used ride.

First and foremost, a licensed engineer must thoroughly inspect the lift to ensure it’s safe for use. The engineer will check the frame’s condition, cables and pulleys, motors, and other mechanical components. If any of these components appear worn or damaged to be functional or safe after installation, they should be replaced before installing the lift.

Second, if any parts have been replaced during the lift’s prior use (such as a new motor), they should also be inspected by an engineer before installation. Those parts should be replaced before installing the lift if they’ve been damaged or worn down over time (for example, due to normal wear-and-tear).

Thirdly, suppose you’re planning on installing an existing passenger elevator in an area with high humidity (like Florida). In that case, you’ll need to ensure that your building’s concrete slab can handle those conditions without cracking or otherwise deteriorating over time because of them (which could lead to serious safety concerns).

Will I Have Access to Technical Support If Something Goes Wrong With My Newly Installed Passenger Lift?

Yes, you will have access to technical support.

We know that you want to feel confident in your purchase, and we are here to help. Our installation technicians are highly trained and expertly skilled to handle any problem. If something goes wrong with your lift after it’s installed (and not because of something that happened during the installation process), we’ll do everything we can to ensure things get fixed quickly.

Could I Receive Compensation for Any Damages Incurred During The Installation Process of A Passenger Lift?

Yes, you could receive compensation for damages incurred during the installation process of a passenger lift. However, it is essential first to understand that two types of injuries could be related to your situation: direct and indirect. Direct damages occur due to the installation process, such as damaged flooring or wall panels. These should be covered by your insurance policy and can be compensated for by your insurance company.

Indirect damages are those that happen later and were not directly caused by the installation process—for example, if you fall down the stairs after installing a new lift because there is no handrail installed yet. These indirect damages would not be covered by your insurance policy but could be compensated for if they were reported immediately after they happened and without any delay in filing.

Is There Anything Else I Should Consider When Comparing Installation Providers for My New Passenger Lift?

There are a few other things to consider when choosing an installation provider.

First, you should ask about the company’s experience with the type of lift you’re looking for. If you’re buying a stairlift for your elderly relative who needs to get up and down from the first floor of their home, then it doesn’t make sense to use a company that only installs elevators.

Second, ask about how long they’ve been in business. A new company might offer lower prices than an older one. Still, if they don’t have the capital or experience necessary to keep the equipment running smoothly over time, you could end up paying more for repairs than it would have cost for a more established company.

Finally, ask about their warranty policy and service contract options. This is especially important if you’re buying a lift that’s going to be used by someone who isn’t as mobile as they used to be—you’ll want to know that they’ll be able to assist when something goes wrong so that your loved one doesn’t have to use improvised solutions like chairs or stools just because no one came when called! If you still have questions, don’t hesitate to Contáctenos.