What Are Freight Elevators?

Freight elevators are specialized lifting systems that transport heavy goods within commercial buildings such as warehouses, distribution centers, and retail stores.

These elevators are specifically built to handle the rigorous demands of industrial environments and provide a reliable solution for vertical material movement.

With their sturdy construction and high load-bearing capacity, commercial freight elevators can efficiently transport large, bulky items, pallets, equipment, and vehicles.

They are equipped with spacious dimensions to accommodate sizable loads and are often equipped with safety features such as reinforced doors and secure loading platforms. Installing commercial freight elevators requires careful planning and adherence to safety regulations to ensure smooth and secure transportation of goods.

Contact our engineers for details on freight elevator ordering! Click here!

What Are the Key Features of Freight Elevators

Freight elevators come with several key features that make them ideal for handling heavy cargo in industrial and commercial settings.

One of the prominent features is their substantial load capacity. These elevators are engineered to transport goods weighing several thousand pounds, allowing for efficient and hassle-free movement of heavy items.

Freight elevators typically feature spacious dimensions and sturdy construction to accommodate bulky and oversized loads. They are equipped with robust door systems, interlocks, and safety sensors to ensure safety during operation.

Also, industrial freight elevators often offer customizable options such as specialized flooring, adjustable shelving, and advanced control systems, catering to the specific needs of different industries and optimizing logistical workflows.

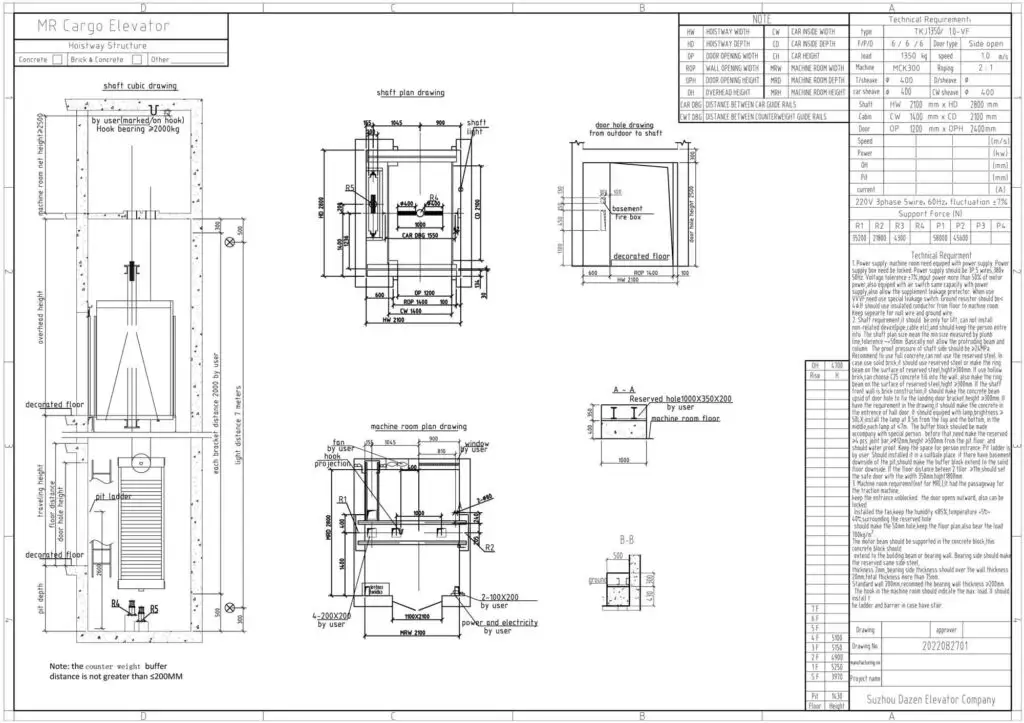

Freight Elevator Dimensions

The cabin of a freight elevator is required to have a minimum height of 8 feet (2.4 m), width of 6 feet (1.8 m), and depth of 5 feet (1.5 m) to accommodate large items.

If the counterweight is mounted on the side, the width of the shaft should be the cabin width plus 4.3 feet (1.3 m), and the depth of the shaft should be the car depth plus 2 feet (0.6 m).

For a rear counterweight, the shaft width should be the cabin width plus 3 feet (0.9 m), and the shaft depth should be the car depth plus 4 feet (1.2 m).

Contact our freight elevator experts!

Freight Elevator Cost

The price range for a freight elevator typically falls between $25,000 and $60,000, with various factors influencing the exact cost. These factors include load capacity, number of floors served, size, MR or MRL configuration, and door opening mechanism.

Higher floor counts and load capacities generally result in higher prices. MRL elevators tend to be more expensive than those with a separate machine room, as they incorporate machinery within the shaft.

Freight elevators with two entrance doors are also pricier compared to open-through door configurations. It’s important to note that these are general guidelines, and consulting with elevator manufacturers or contractors is recommended for accurate pricing based on specific project requirements.

5 Key Applications of Freight Elevators

Freight elevators find diverse applications in industries and facilities that require the efficient and safe movement of heavy goods, enhancing productivity, and streamlining logistics.

1. Warehouses and Distribution Centers: They enable the quick and safe transportation of heavy items, pallets, and bulk materials, enhancing the overall workflow and productivity of these facilities.

2. Manufacturing Plants: They ensure smooth and timely delivery of materials to various production areas, reducing downtime and optimizing the manufacturing process.

3. Retail Stores and Shopping Centers: They enable the effortless transfer of inventory from storage areas to sales floors, ensuring efficient restocking and replenishment of products.

4. Hospitals and Healthcare Facilities: They assist in efficient logistics within hospitals, enabling the movement of essential resources between different departments and floors.

5. Construction Sites: They enhance productivity and safety by reducing the need for manual handling and minimizing the risk of accidents.

Different Types of Freight Elevators

Freight elevators come in various types, each designed to meet specific requirements and accommodate different types of cargo. Some common freight elevators include:

Traction Freight Elevators

Traction freight elevators use a system of ropes and counterweights to lift and lower cargo. They are more energy-efficient and are commonly used in high-rise buildings or facilities with heavy-duty lifting needs.

Hydraulic Freight Elevators

These elevators use hydraulic power to lift heavy loads. They are known for their smooth and quiet operation and are suitable for low to medium-rise buildings.

Machine Room-Less (MRL) Elevators

MRL freight elevators eliminate the need for a traditional machine room by integrating the machinery and components within the elevator shaft or hoistway. They save space and offer flexible installation options, making them popular where space is limited.

Material Lifts

Material lifts, also known as vertical reciprocating conveyors (VRCs), are designed for transporting goods between different levels within a building. They are often used in industrial settings and warehouses.

Car Elevators

Car elevators are specialized freight elevators designed to transport vehicles. They are commonly found in car dealerships, parking garages, and automotive service centers.

Dumbwaiters

While typically smaller, dumbwaiters are also considered a type of freight elevator. They are used for transporting small goods, food, or supplies between different floors, commonly found in restaurants, hotels, and residential buildings.

Methods of Loading Goods on Freight Elevators

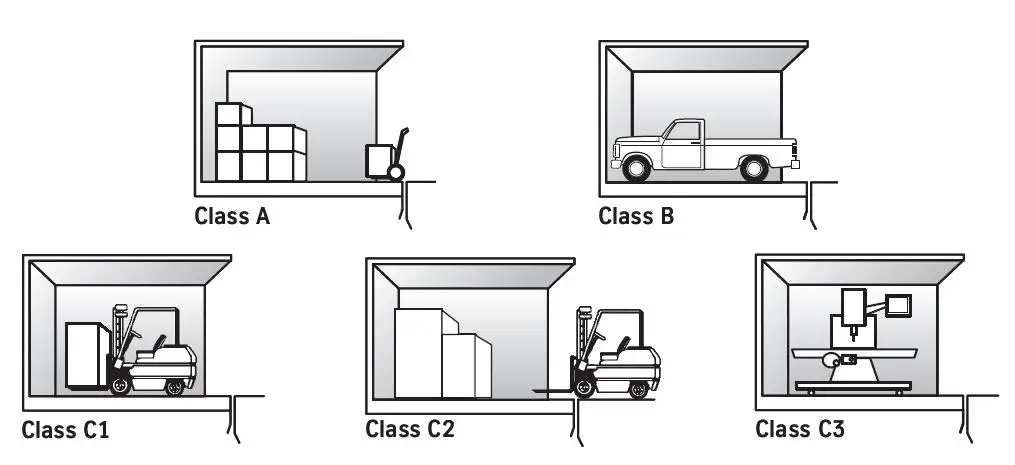

Freight elevators are categorized into different loading classes based on their intended use and the type of goods they are designed to transport. The loading classes specify the weight capacity and other specifications of the elevator.

The specific loading classes can vary slightly depending on the elevator manufacturer, but the following are commonly recognized:

Class A: Light Duty – General Freight Loading

These elevators are designed for light loads and typically have a weight capacity of up to 2,000 pounds (907 kilograms). They are commonly used for transporting smaller goods in commercial buildings.

Class B: Medium Duty – Heavier Freight Loading

Medium-duty freight elevators are capable of handling heavier loads, typically up to 3,500 pounds (1,587 kilograms). They are commonly used in warehouses, factories, and industrial settings.

Class C1: Heavy Duty – Motor Vehicle Loading

Heavy-duty freight elevators have a higher weight capacity, often ranging from 5,000 to 10,000 pounds (2,268 to 4,536 kilograms). They are designed to transport larger and heavier items, such as machinery or vehicles, and are commonly found in industries like manufacturing, construction, and automotive.

Class C2: Extra Heavy Duty – Industrial Vehicle Loading

Extra heavy-duty freight elevators are designed to handle extremely heavy loads. They have weight capacities exceeding 10,000 pounds (4,536 kilograms) and are commonly used in industries with specialized transportation needs, such as mining or heavy equipment.

Benefits of Installing a Freight Elevator in Your Business

Installing a freight elevator in your business can bring about a multitude of benefits, revolutionizing your material handling processes and streamlining your logistics operations. Here are the top ten benefits you’ll get for installing a freight elevator:

- Increased productivity and efficiency in material handling

- Streamlined logistics and reduced manual labor

- Safe and secure transportation of heavy goods

- Ability to handle large and bulky items

- Improved workflow and reduced downtime

- Enhanced safety features for employees and cargo

- Cost savings by optimizing space utilization

- Flexibility in accommodating diverse types of cargo

- Facilitates multi-floor operations in warehouses and distribution centers

- Enhances overall operational capacity and scalability

Factors to Consider When Selecting a Freight Elevator

When selecting a freight elevator, it is crucial to carefully consider various factors to ensure the right choice for your specific needs and requirements. From weight capacity to safety features, each aspect plays a significant role in determining the elevator’s functionality, efficiency, and overall suitability.

Here’s a checklist you can use to select the best freight elevator:

| Factors | Minimum Value You Should Go For |

| Freight elevator capacity | Minimum capacity of 5,000 lbs (2,268 kg) to accommodate heavy loads. |

| Freight elevator dimensions | Sufficient dimensions of at least 8 ft (2.4 m) in height, 6 ft (1.8 m) in width, and 5 ft (1.5 m) in depth to accommodate large items. |

| Speed and travel distance | Adequate speed of 150 ft/min (0.76 m/s) and a travel distance of at least 3 floors. |

| Door configuration | Suitable door configuration such as sliding doors or folding gates for easy movement of goods. |

| Safety features | Essential safety features like door sensors, emergency stop buttons, and overload protection systems. |

| Controls and automation | Advanced features such as programmable floor stops or destination dispatch systems for enhanced efficiency. |

| Power requirements | Compatible with your building’s power supply of at least 208V, 3-phase, 60Hz electrical system. |

| Maintenance and service | Provided by a reliable manufacturer with a responsive service network offering regular maintenance and quick response times for repairs. |

| Freight elevator installation | Professionally installed by certified technicians to ensure safe and efficient operation. |

| Building codes and regulations | Compliant with all relevant local building codes and regulations. |

| Budget | Within your allocated budget range of $30,000 to $50,000, including installation, maintenance, and modifications. |

Get advice from Dazen experts on freight elevators!

Freight Elevator Safety Standards and Regulations

Freight elevator safety standards and regulations vary by country and jurisdiction, but there are some common elements. In general, freight elevators must meet strict safety requirements to ensure the protection of workers and the proper handling of goods.

These standards typically cover areas such as elevator design, installation, maintenance, and operation. They may include specifications for load capacity, safety devices (such as door interlocks and overspeed governors), emergency communication systems, lighting, and ventilation.

Compliance with these standards is usually enforced by government agencies or regulatory bodies responsible for elevator safety. It is important for building owners and operators to adhere to these regulations to prevent accidents and ensure the safe transportation of goods.

Freight Elevator vs Passenger Elevator: What’s the Difference?

Speed

The speed of a freight elevator is slow, typically around 0.5m/s. On the other hand, passenger elevators have a wider range of speeds, ranging from 1 m/s to 7 m/s.

Load Capacity

Freight elevators are designed to carry heavier loads, typically above 1000 kg. In contrast, passenger elevators have a load capacity ranging between 450 kg and 1600 kg.

Door Configuration

Due to the larger load and size of freight elevator, it is generally configured with two side doors or four middle division doors to accommodate the larger items being transported. While passenger elevator is configured two middle division doors.

Interior Finish

The interior of freight elevators is focused on functionality rather than luxury. These elevators feature minimal decoration, with car and door panels made of painted steel plates, and steel flooring for enhanced durability.

In contrast, passenger elevators are typically designed with a greater emphasis on luxury and aesthetics. The interior of these elevators is decorated to provide a comfortable and enjoyable riding experience.

Interior Finish

The interior of freight elevators is focused on functionality rather than luxury. These elevators feature minimal decoration, with car and door panels made of painted steel plates, and steel flooring for enhanced durability.

In contrast, passenger elevators are typically designed with a greater emphasis on luxury and aesthetics. The interior of these elevators is decorated to provide a comfortable and enjoyable riding experience.

Dazen Freight Elevator: The Best Freight Elevator You Can Get

At Dazen Elevator, we take pride in being the leading manufacturer of freight elevators in China. We offer the best solutions for heavy-load transportation in commercial buildings, industrial plants, logistics centers, and warehouses. Our freight elevators are designed to meet the demands of various industries, providing convenient and efficient transportation for heavy cargo such as forklifts, pallets, and containers.

Equipped with heavy load protection systems, limit switches, and safety doors, our elevators ensure the utmost safety during operation, preventing accidents and ensuring smooth transportation of goods. The durable materials used in constructing our elevators, such as crash strips and painted steel plates, guarantee their ability to withstand the rough handling of goods and frequent use.

One of the key features of our freight elevators is the larger door opening space, allowing for easy and unrestricted access to voluminous cargo. We offer various door-opening modes to cater to different needs, including two-panel sliding doors, center-opening and double-folded types, and single-way and double-way doors.

With a maximum capacity of up to 10,000kg and a speed range of 0.25-1m/s, our freight elevators offer superior travel performance and can handle the transportation needs of diverse industries.

Regarding installation and maintenance, you can rely on our professional teams in over 80 countries. With our award-winning team from Otis, we provide timely and efficient solutions, ensuring your elevator operates smoothly throughout its lifespan.

With our extensive experience working with renowned brands like FUJI and Sanyo and supplying parts for Thyssenkrupp and Schindler, we have earned the trust of major players in the industry.

So, Contact us Today!