Elevator Traction Control System

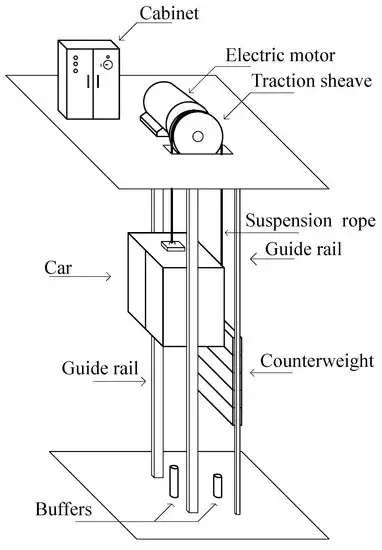

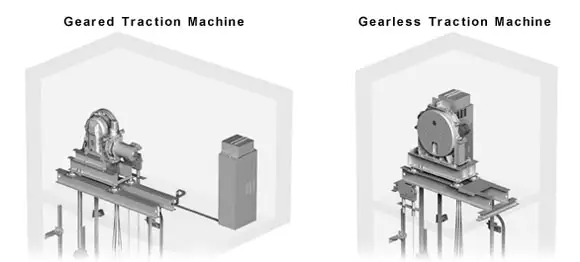

The elevator’s traction system serves the purpose of generating and transmitting power to facilitate the elevator’s movement. This system primarily comprises the traction machine, traction rope, guide sheave, and counter rope sheave. The traction machine is responsible for supplying the necessary power to propel the elevator. It consists of components like an electric motor, traction sheave, shaft coupling, reduction box, and electromagnetic brake.

The pulling wires are affixed to both the elevator car and the counterweight, using the friction between the wire rope and the pulling sheave to maneuver the car in upward and downward directions. Meanwhile, the guide pulley plays a crucial role in maintaining the separation between the car and the counterweight. Employing a compound winding design can also enhance the pulling force exerted by the system.

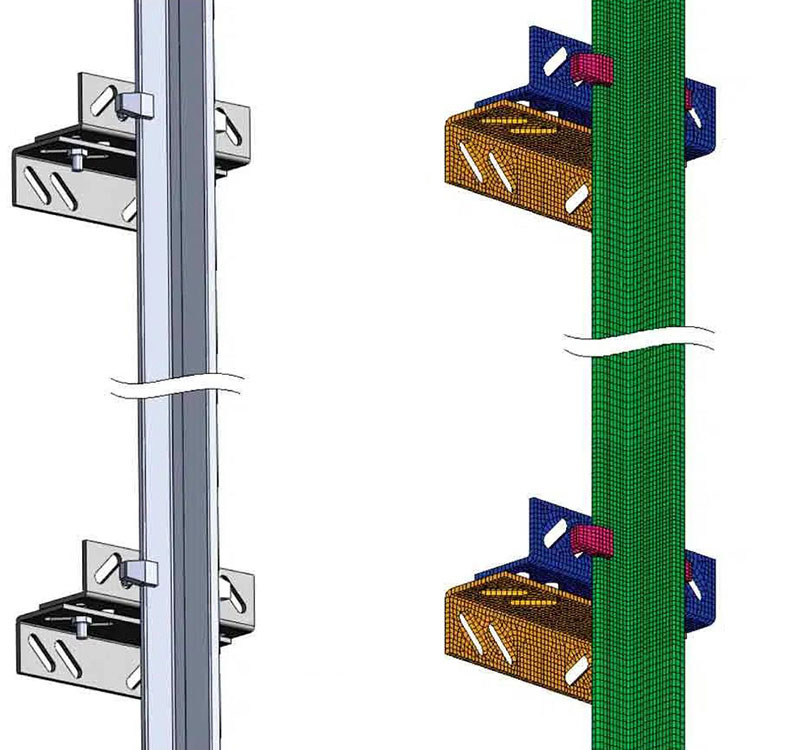

Elevator Guide System

The guide system comprises guide rails, guide shoes, and guide frames. Its essential role is to constrain the range of motion for both the elevator car and the counterweight. This restriction ensures that these components are capable of solely moving vertically along the guide rail.

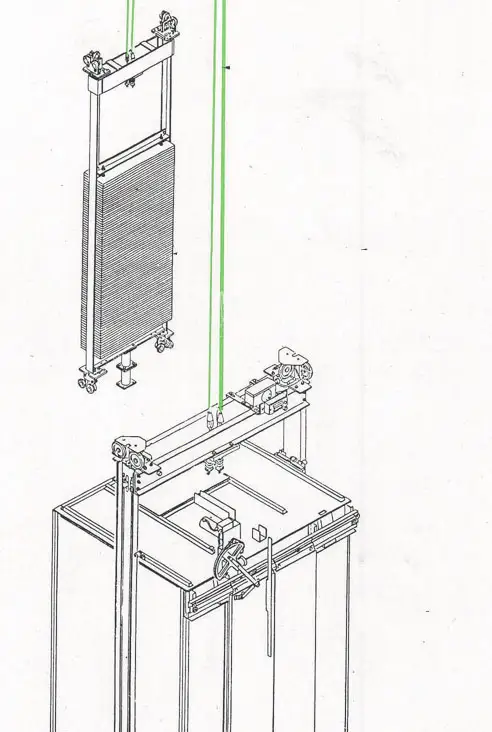

Elevator Door System

The elevator door system encompasses components such as the car door, floor door, door opener, door locking device, linkage mechanism, and more. The car door is positioned at the car’s entrance, comprising the door itself and the door guide frame. Similarly, the floor door is situated at the entrance of each floor station. The door opener, located within the car, serves as the power source for both the car and the floor doors.

The primary purpose of the door system is to effectively seal off the entrances of both the floor stations and the elevator car.

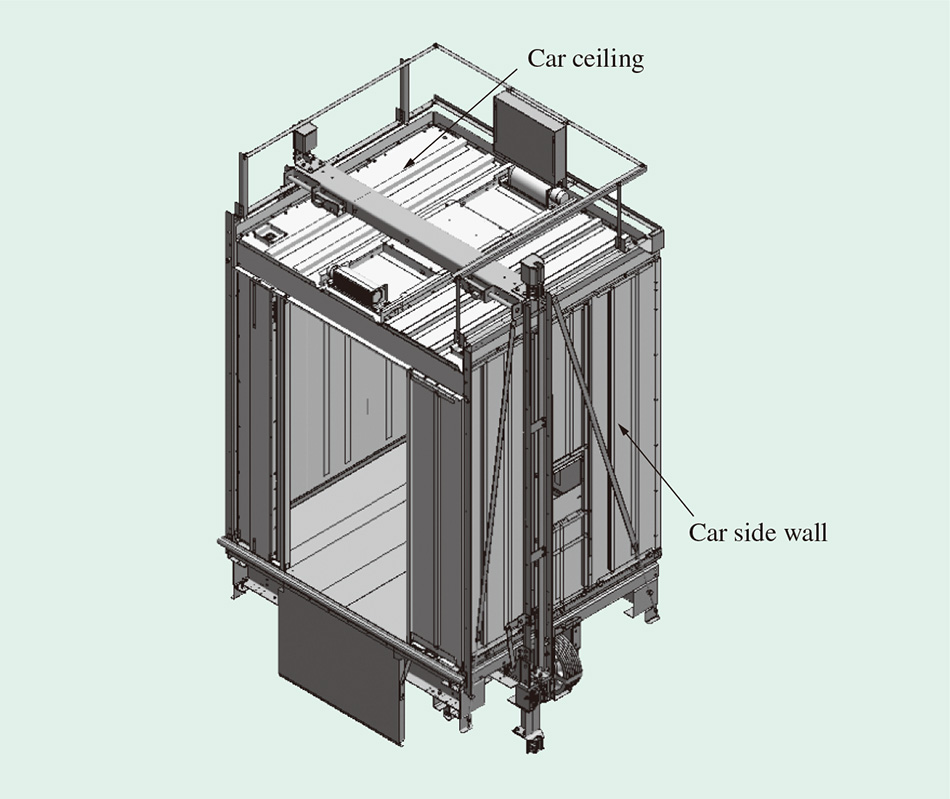

Elevator Car

The elevator car serves as a vital component designed to convey passengers or cargo. It is comprised of two main parts: the car frame and the car body. The car frame acts as the load-bearing structure for the car body, consisting of cross beams, columns, bottom beams, and diagonal rods. The car body itself encompasses the car’s bottom, walls, and ceiling, as well as features like lighting, ventilation systems, decorative elements, and control button panels.

The dimensions of the car’s interior space are determined by the designated specifications of the elevator. Meanwhile, the size of the car body space is contingent upon factors such as the rated load capacity and the intended number of passengers the elevator is designed to accommodate.

Elevator Counterweight System

The elevator counterweight system comprises the counterweight and the weight compensation device. Its primary role is to achieve a relative equilibrium in the weight distribution of the elevator components. By maintaining a controlled weight differential between the elevator car and the counterweight during operation, this system ensures that the elevator’s traction mechanism functions smoothly and as intended.

Elevator Electric Drive System

The electric drive system encompasses components such as the traction motor, power supply system, speed feedback device, speed regulator, and more. Its primary role is to govern and regulate the elevator’s speed. The traction motor serves as the core power generator for the elevator, and depending on the elevator’s configuration, either an AC motor or a DC motor can be employed.

The power supply system is responsible for providing the necessary electrical energy to drive the motor. The speed feedback system is designed to furnish the elevator’s running speed signal, which is essential for the proper function of the speed control system. Typically, a speed generator or speed pulse generator is linked with the motor to achieve this. Finally, the speed control device is responsible for managing and controlling the speed of the traction motor.

Elevator Control System

The electrical control system of an elevator comprises components such as a control device, a manipulator, a leveling device, and a position display device. Its primary purpose is to manage and oversee the elevator’s operation.

Among these components, the control device directs the elevator’s operation based on the elevator’s operational logic and functional requirements. It is situated within the control cabinet located in the machine room. The control device enables elevator operation through the buttons inside the elevator car as well as the call buttons located on the hall doors.

The leveling device is a specialized control component that transmits leveling control signals to ensure precise alignment of the elevator car. This ensures that the elevator car arrives at each floor in a level position, optimizing passenger comfort and safety.

Elevator Safety System

The safety protection system encompasses a variety of both mechanical and electrical safeguards. Its core purpose is to guarantee the secure operation of the elevator and to avert any accidents that might pose a threat to personal safety. This system includes crucial components such as the elevator speed limiter, safety clamp, rope clamp, buffer, safety contact plate, floor door lock, elevator safety window, elevator overload limiting device, and limit switch device.