As it is general knowledge, elevators are very important equipment in a building that transports people to and fro different floors, making it one of the first things to be installed if you are considering building a structure with floors. Now, to house this elevator, we have the elevator shaft. Elevator shafts are structures encompassing the elevators to ensure they are secured and comfortable.

What is an Elevator Shaft?

An elevator shaft is a tall enclosed space in a building that helps elevators or lifts—depending on what you call it, move up and down without problems. Visualize it like the elevator’s personal space or road in the building. The shaft is designed to house the elevator moving parts and other assets for the safety of users. Now, taking an inward look at the shaft, you’ll find out that the shaft is made of fireproof materials and is designed to remain fortified in case of an accident.

The shaft houses the elevator car—to transport users and luggage, a counterweight —to ease movement, and rails—to protect the elevator. Basically, the safety of the elevator is dependent on how solid the shaft is.

You can put it this way: just like there are specifically built race tracks for fast cars to conduct their movement, the elevator shaft serves as a conductor for the elevator cabin— The elevator cabin navigates the building through the tracks of the shaft, ensuring a stable and risk-free movement of users along building floor through and fro. Now, we will discuss the components of an elevator shaft.

Components of an Elevator Shaft

There are multiple parts in an Elevator shaft, starting with the:

Hoistway: The hoistway is the main component of the elevator shaft. It houses the pathway through which the elevator car and users move. It helps users move to and fro the building.

Elevator Car: The elevator car or cabin is the compartment that moves users and luggage through the building. It features doors that serve as a pathway of entry for you to enter and exit the cabin or car.

Counterweight: The counterweight assists with balancing the elevator to make it stable and aid movement. It is connected to the car via the opposite side of the rope.

Machine Room: The machine that wheels the elevator cabin is kept in a chamber at the top of the elevator shaft. This machine features a unique motor, gears, and unique features that help move the elevator between floors.

Shaft Ventilation: Now, it is important the ventilation in the cabin is clean and not too hostile, so having a quality ventilation system is not bargainable. A clean ventilation system puts the users at ease and ensures smooth usage of the elevator. A good ventilation system also prevents overheating.

Pit: The pit is the space under the ground floor. It helps give the elevator clearance on the lowest floor.

Fireproof: Elevator shafts are made of fireproof materials. The purpose of this is to prevent fire from having easy movement around the building if there is a fire accident.

Guide Rails: Guide rails are unique tracks on the elevator shaft walls. They help the elevator cabin remain stable during movement.

Overhead Clearance: This feature is an empty space above the elevator shaft on the topmost floor of the building. It accommodates the elevator at the topmost floor.

Shaft Lighting: To give visibility to passengers and the elevator’s maintenance crew. The shaft lighting system is very important and mounted within the hoistway. Next, we would take a look at the different types of elevator shafts.

What Are The Different Types Of Elevator Shafts?

Concrete Elevator Shaft

So, what is a concrete Elevator shaft? A concrete Elevator shaft functions as a safety pathway to help the elevator move efficiently. It is constructed with reinforced concrete to ensure durability and strength.

This concrete absorbs noise, stress, and vibration to ensure smooth usage. The concrete is usually designed to accommodate different elevator types and enhance the beauty of the elevator. It also features guide rail, emergency brakes, and backup power—to ensure the safety of the users.

Steel Structure Elevator Shaft

Contrary to the concrete frame, the steel framework is constructed out of robust, solid, and formidable steel or iron components. But that doesn’t make it any better than the concrete framework because it just equally creates a secure pathway for the elevator car to move through the building reliably. The steel framework’s strength and reliability make it solid enough to absorb the stress and vibration created during motion.

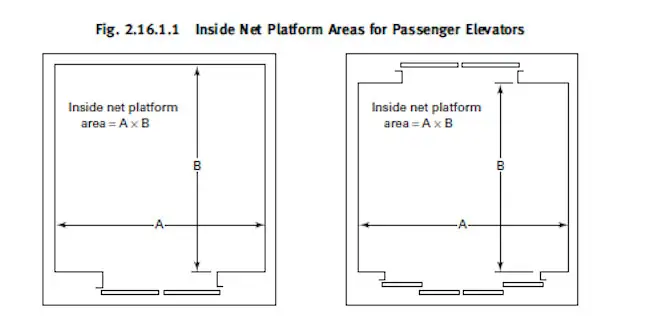

Elevator Shaft Dimensions

The smallest size for an elevator shaft is around 1250mm * 1450mm. This size is usually used in villa elevators. The common size for an elevator shaft designed to host an 8-passenger, 630kg elevator is about 1700mm by 2100mm.

it’s important to note that elevator shaft dimensions can vary based on factors such as the type of elevator, building codes, and design considerations.

To ensure you are within the safety standards and regular, we recommend you seek the advice of a professional elevator service provider to help you determine the optimal dimensions.

At Dazen Elevator, we specialize in compact shaft designs and prioritize superior safety measures for elevators. Feel free to reach out to us for more detailed information regarding your elevator needs.

How are Elevator Shafts Constructed?

Design and Planning

Designing an elevator shaft is a collaborative effort between Architects, Engineers, and Elevator Manufacturers. This design is usually created around the building layout, elevator type, and the applicable building codes.

The shaft dimensions, clearance, pit depth, overhead clearance, and door opening are agreed upon during this process.

Foundation and Pit Construction

The foundation supports the elevator shaft structure and is crucial to the construction. Also, you can include excavation and the installation of a reinforced concrete foundation if you wish.

A pit is dug out beneath the elevator shaft. This pit houses the counterweights and other mechanical components. It is crucial to note that the spec of your elevator determines the depth of your shaft pit.

Shaft Structural Framework

The vertical shaft structure is constructed out of concrete, steel, and sometimes a mixture of both. Concrete can be used synchronously with steel bars to form the shaft wall. This process supports the shaft and helps the elevator move securely.

Elevator Hoistway Doors and Opening

During movement, each floor where the elevator will stop has an opening. This opening is known as the door opening. Note that this opening must match the dimensions of the elevator doors.

Also, steel and other framing materials are included around the opening to give structural support for the doors to ensure the safety of users.

Overhead Clearance and Machine Room

The elevator systems parameters govern the overhead clearance, and the clearance helps with flawless movement of the elevator car and counterweight. In some situations, the elevator’s machine room is placed at the top of the shaft to contain the elevator’s mechanical components, like the motor and control system.

Elevator Car Installation

When the structural framework is already in place, the elevator car and all important components are installed within the shaft—the car is connected to guide rails running along the shaft. This attachment ensures the user experiences a smooth ride while going through floors.

Safety Features and Testing

Door sensors, brakes, and speed governors are all installed and tested to ensure they work properly. The elevator is thoroughly tested to confirm the degree of safety it offers.

Finishing Touches

The elevator shaft is then infused with Fireproof materials, light, and other user safety features. The interior is developed and finished to meet the function of the building.

Conclusion

To conclude, elevator shaft building is a crucial process of building design. It incorporates architectural vision, engineering precision, and detailed attention to safety codes and regulations. Elevator shafts offer the core framework for a smooth and secure passenger elevator ride. It requires unique insight and intelligence from architects, engineers, and elevator manufacturers to fit the unique characteristics of different elevator systems.

At Dazen Elevator, we offer you years of expertise and are focused on delivering dependable and innovative elevator solutions. Our emphasis on elevated safety measures, durability, and state-of-the-art systems helps us guarantee that our services adhere to the utmost standards of the industry. Reach out to us today.