The first passenger elevator debuted in 1845 and since then only two major types have taken off. One is a hydraulic elevator, which uses a hydraulic piston to lift and lower down the lift. The other is a classic traction elevator that works on a pulley system which requires a machine.

These traction elevators can be further broken down into two major types based on their components and functionality. Geared and Gearless traction Elevators. Both of them come with their complexity and functionality. While traction elevators have a complex system, the difference between the two is fairly simple.

Let’s explore both of these traction elevators in terms of their uses and functionality.

What’s a Geared Traction Elevator?

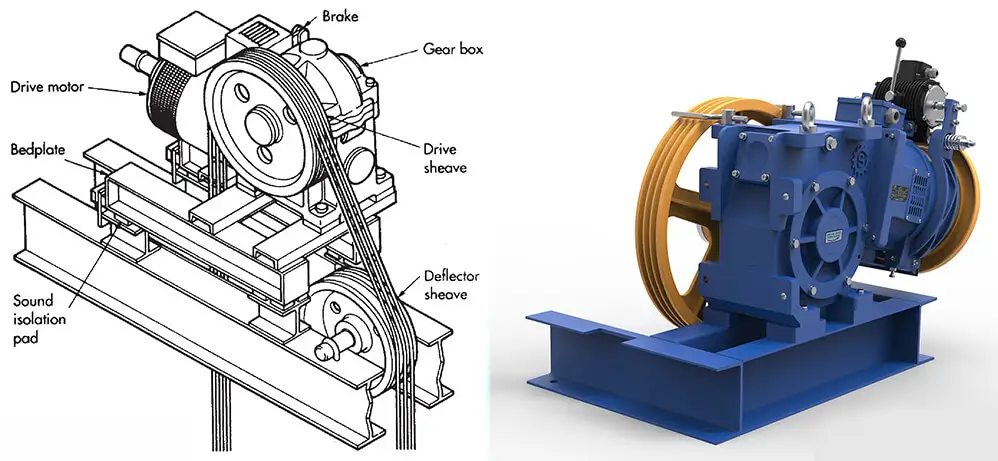

A geared traction machine has a gearbox attached to the AC or DC motor of the machine. The gearbox is connected to the motor, and it drives a wheel that facilitates the movement of the rope. This mechanism makes them energy-efficient as well.

This type of elevator is ideally utilized for a midsized building up to 300 feet. Moreover, it has a probability of reaching up to a speed of 500 feet per minute. Which ideally is not the fastest yet it is faster than many of the elevators.

What’s a Gearless Traction Elevator?

In a gearless traction machine, the wheel is directly attached to the electric motor, causing the drive sheave to rotate instantly. This rotation of the drive sheave is responsible for the elevator cab’s upward and downward movement.

To differentiate a gearless machine from a geared one, you can easily observe if all components move uniformly in one direction.

The gearless machine has an AC motor and a higher lifting capacity. This particular functionality enables this type of machine to be ideally used in high-rise buildings.

Differences Between Geared and Gearless Traction Elevators

Traction Elevators work on a simple function i.e. the pulley system. The cab is attached by either ropes or belts to a wheel on the motor. The motor turns the wheel to lift the cab up and down. This system also uses a counterweight to balance the load on the cab hence being more energy-efficient.

We can compare geared and gearless elevators in multiple categories to determine which one’s the best.

Height Elevation

As traction elevators work on the pulley system mechanism we need to be mindful of friction when considering which type of elevator to put in.

Geared elevators can be efficient in building up to 20 stories, but after that, we need to consider the effect of the added weight of the gearbox.

In high rises the speed and weight matter a lot. In this case, the gearless direct-drive system is lighter in weight. Thus reducing friction and energy loss. In turn, they are faster.

Hence it depends on the size of the buildings. Do your research to make a sound decision on whether a geared or gearless machine will be more beneficial for your building.

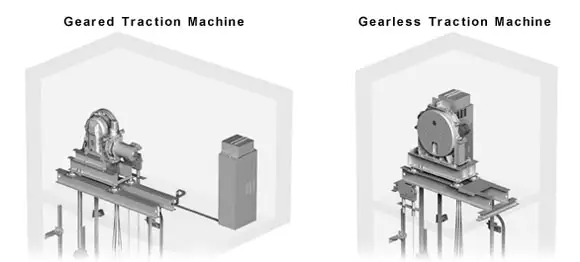

The Need for a Machine Room

One of the major differences between geared and gearless elevators is the machine room. The machine room has the wheel and the electric motor which is placed above the shaft.

In gearless machines as the wheel is attached directly to the motor, there is no need for a machine room. Due to this gearless elevators are also known as Machine-Room-Less (MRL) Elevators.

Machine rooms are ideally positioned above the elevator shaft and are important aspects of a building design. These rooms require adequate lighting and climate control. They need to be in an air-conditioned setting to avoid overheating due to friction.

Due to their significant size, architects must plan for them when designing the building. Thus this can be seen as a drawback of geared elevators.

Speed

Because of their base structure, there is a significant difference in the weight of these two types of elevators. Enough to affect their performance such as speed. On average, geared traction elevators can move up to the speed of 152 meters per minute at a distance of up to 75 meters.

On the other hand, a gearless traction elevator can move at a speed of 610 meters per minute and at a maximum height of 600 meters. Despite this, they both have the same load capacity in terms of passenger weight.

Hence which elevator to choose depends on the specification of the particular building. One of the most important is the height of the building.

Taking height and speed into consideration, gearless traction elevators are a winner. Especially in taller buildings.

Design

The aesthetic of the elevator needs to match that of the building. It is crucial so it all looks coherent, particularly in places like hotels and offices. Modern and on theme is something that is a priority in these places.

Similarly, due to the lighter weight of gearless elevators, the elevator is comparatively less noisy. They have a very smooth landing and leveling functionality.

The motors on the gearless elevator make less vibration in the cabin while moving and have a smoother stopping and moving function. This contributes towards a smoother and more comfortable elevator ride experience.

When we think about the design of the elevators in particular, we ourselves judge the worth or class of a place by its elevators. Modern and sleek elevators depict high-class or high technology.

If it’s the aesthetic of your place, then the compact and chic functional design of a gearless traction elevator is the way to go. On the other hand, if you are into old timely charm or history then a geared elevator would go well.

Consumption of Energy

In today’s world and time being energy-efficient is a trend. Of course for protecting our environment, people are far more aware of energy consumption and prefer to lean towards energy-efficient gadgets.

Gearless elevator motors can be more compact compared to geared elevator motors, mainly because they lack the gear components. In fact, gearless motors can be less than half the size of geared motors.

This compact size is advantageous in terms of energy efficiency since smaller motors require less electricity to operate. Moreover, the absence of a gear unit reduces friction and in turn energy loss.

Downsizing the motor also leads to smaller overall components, ultimately enhancing the elevator’s performance and making gearless motors a more attractive choice.

Maintenance

One of the most important components of any machinery is its maintenance. Because of a separate gear unit, geared elevators have a comparatively larger engine. Furthermore, their motors need regular greasing. This needs to be done regularly which adds to maintenance time and cost. On the other hand, gearless elevators are made of smaller components, which are easy to replace and maintain. Moreover, it does not require any use of oil. Thus making this option easier to maintain.

Pricing

Geared traction elevators are cost-effective to install. In the separate gearbox units smaller motors, ropes, and belts can be used that are cheaper to install. However, due to the presence of a gearbox, unit maintenance is difficult. Along with oiling to maintain low friction and avoid any mechanical loss, the maintenance of the gearbox unit is costly.

On the flip side, because of no gearbox, a gearless traction elevator requires large motors and sheaves, amounting to high installation costs. This is technologically advanced hence why components are expensive when installed upfront. However, the entire design is energy-efficient. The components do not need regular mechanical maintenance so you are saving on maintenance costs by a lot. This is an important factor to consider in tall buildings where you have to watch out for increasing energy consumption and find ways to reduce it.

Which One to Choose?

After discussing the pros and cons of both types of traction machines, it heavily depends on the type of building you are installing the machine in. the aesthetic, size, and upfront investment available.

For taller high-rise, modern buildings that have a huge investment available for construction, a gearless traction elevator is the way to go.

However, if it’s a low-rise building and the initial installation cost is less, then a geared traction elevator would work as well.

About Dazen Elevator

Dazen specializes in traction elevators, prioritizing precision and innovation in vertical transport. Our range includes passenger, home, hospital, freight, and scenic elevators. We are committed to delivering quality and functionality in every ride.

Whether it’s in busy offices, homes, healthcare facilities, or industrial settings, our traction elevators prioritize safety, reliability, and comfort.

With Dazen, you’ll experience smooth and dependable vertical mobility that enhances your daily life. Contact us now!