What is a Hydraulic Elevator?

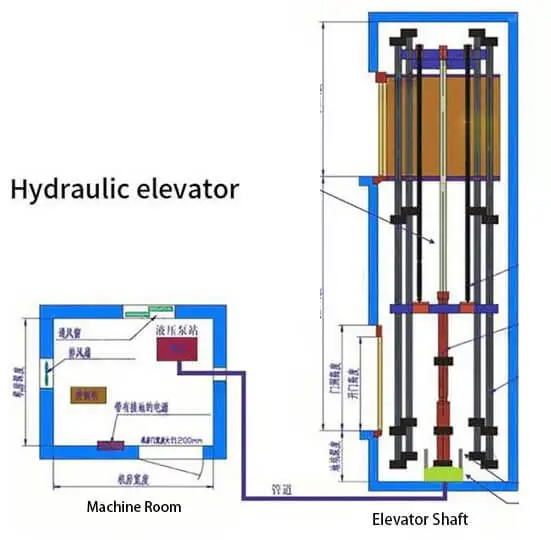

Hydraulic elevators are elevators kinds that are designed to use hydraulic fluids to transport the elevator car and everything in it up and down in a building. It is designed in such a way that the pump forces oil into a cylinder, when then pushes a piston up. This piston is connected to the elevator car so that every time the piston moves, it also causes the elevator car to move.

This type of elevator is mostly used in low or mid-rise buildings. These are usually buildings that have less than 8 stories. These buildings include apartment buildings, manufacturing facilities, warehouses, and office buildings. The hydraulic elevator can only be used in these buildings because it is a slow elevator when compared to traction elevators.

However, hydraulic elevators are designed in such a way that they save more energy than traction elevators. They also cost less to install and cost less to maintain. They also have a smoother ride quality and operate with less noise.

Hydraulic Elevator Components

A hydraulic elevator is made up of several key components that work together to transport the elevator car up and down a building. These include:

1. Hydraulic Cylinder: This is the part of the elevator that is responsible for raising the car. It is also the elevator’s central component. It is made up of hydraulic fluid, cylinder, and piston.

2. Pump: The pump is important as it works to transport the hydraulic fluid to the cylinder. This releases the pressure that allows it to lift the elevator car.

3. Valve: The valve is used to direct the direction of hydraulic fluid flow, either to the reservoir or the cylinder.

4. Reservoir: The reservoir is used as the storage room for the hydraulic fluid.

5. Controller: The controller is an important part of the hydraulic elevator as it is where many operations are carried out. Some of these are door control, floor selection, and safety measures.

6. Motor: The motor is the engine of the whole system, powering the pump. It supplies the elevator with electricity.

7. Car: The elevator car is connected to the hydraulic cylinder by cables or chains and is used to transport people or products.

8. Counterweight: The counterweight is used to balance the weight of the elevator car and its occupants.

9. Safety Devices: These devices are designed to prevent accidents or injuries during the lift. These things include sensors, switches, and brakes.

10. Electrical System: The electrical system is responsible for supplying power for lighting, the controller, and the safety devices.

How Does Hydraulic Elevator Work

Unlike traction elevators that use overhead hoisting machinery, the basic idea behind hydraulic elevators is the use of fluids to move the elevator car and its occupants up and down the building.

The elevator cab is moved by an electric motor that pumps the hydraulic oil into the cylinder to move the piston. The elevators also come with valves that help to control the release of oil into the cylinder. When the elevator car has gotten to where it wants to get to, the valve opens and the oil is released back into the oil reservoir. This action then lowers the elevator car.

How fast a hydraulic elevator moves is determined by the size of the oil pump and that of the piston. The larger the pump and the cylinder, the faster the elevator will be. Also, the fluid used in a hydraulic elevator is often oil-based, with examples like vegetable oil or biodegradable oil.

What Buildings Do Hydraulic Elevators Work Best?

Hydraulic elevators come with such great benefits that they can be used in any type of building. However, there are two factors that can determine how high they can travel, and also where they can be used.

By design, hydraulic elevators require a significantly higher than normal amount of energy to lift the cab. Thus, it is not commonly found in high-rise buildings.

Also, hydraulic elevators are designed to move at speeds of up to 200 feet per minute, which makes them slower than the other types of elevators.

Because of all these factors, hydraulic elevators are often found to be used extensively in buildings up to five or six stories high. Sometimes, but rarely, they are used in buildings up to 8 stories high.

Types of Hydraulic Elevators

Hydraulic elevators come in three main types: holed hydraulic, holeless hydraulic, and roped hydraulic.

Holed Hydraulic Elevators

This type of hydraulic elevator is sometimes referred to as direct-acting lift. Here, the hydraulic cylinders are driven into the ground to a depth that is equal to the height the elevator will rise. Once this is done, the elevator car is then mounted on a piston that travels inside of the cylinder. When hydraulic fluid is released into the cylinder through a valve, the car would rise. When the fluid returns to the reservoir, the car would then descend.

Holeless Hydraulic

This type of elevators is used in existing buildings or in areas with bedrock, a high water table, or unstable soil conditions locations. This is because drilling isn’t required for this kind of elevator. So, instead of having a cylinder buried underground, this kind of hydraulic elevator uses hydraulic jacks located above ground level. These jacks are often placed on either side of the elevator car. The principle for ascending and descending here is the same with that of the holed hydraulic elevator.

Roped Hydraulic

Roped hydraulic elevators use a combination of cables and a piston attached to a sheave to lift the elevator car. This allows for a smooth riding experience without the need to dig a deep hole in the ground.

Here, the hydraulic jack is positioned in the hoistway between the rails, with a pulley attached to its top. Also, two hoisting cables connect the system: one end is attached to the elevator cab, and the other end is secured to a fixed point at the base of the rails. Then, the controller and hydraulic pump are located in a nearby machine room. This type of elevator requires only a shallow pit.

The roped hydraulic system is also designed to use the pulley to give it a 2:1 movement ratio. This means that for every 1 foot that the jack moves, the cab moves 2 feet. This is how the unit can operate without digging a deep hole for the hydraulic jack. Also, roped hydraulic systems require a governor because the rope is holding the car up, and there is a risk of the car free falling if the rope breaks.

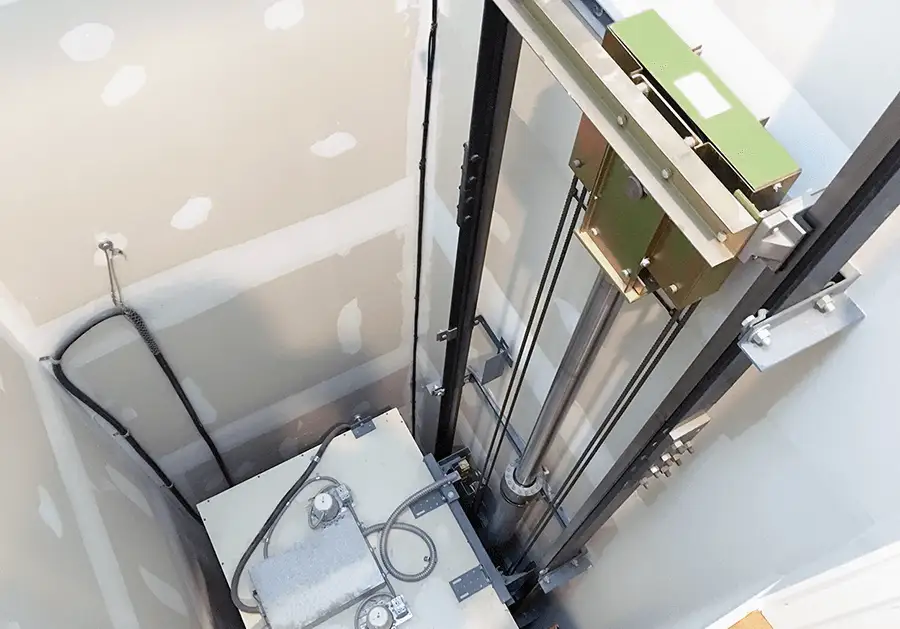

There also is the machine room-less machinery. This hydraulic elevator does not require a separate room to house the machinery for the elevator. Here, the machinery is housed and installed on the elevator pit. This kind of hydraulic elevator is beneficial as it saves cost and time in construction. It also maximizes the available space in a building.

Advantages of Hydraulic Elevator

If you’re looking at installing a hydraulic elevator in your building, here are some of the advantages you stand to gain from doing it:

Hydraulic elevators save more energy than other types. This is due to the fact that they use less electricity than others.

Hydraulic elevators are also generally known to produce less noise than traction elevators. This is due to their design as they do not have any moving parts, such as cables or sheaves, as well as no loud motors or other machine parts.

The lack of moving parts also means they require less maintenance compared to others.

Their simple design also means they are less expensive and quicker to install and operate than other types of elevators.

The option of having a machine room-less configuration means they would take up a smaller portion of space compared to others.

There also is no need for reinforcement, as the cylinder that lifts the elevator cab is supported by the ground underneath. Although this works only for holed hydraulic elevators.

Disadvantage of Hydraulic Elevator

However, installing a hydraulic elevator also comes with some disadvantages:

Its use is limited to just low and mid-rise buildings.

These elevators can also be affected negatively by things like extreme temperatures and oil contaminants.

The hydraulic oil can also leak into an aquifer which can cause serious problems for the environment. This is usually seen in older hydraulic elevators. For older models too, they can be very noisy as the motor is located outside of the tank.

Hydraulic Elevator Cost

The cost of purchasing and installing a hydraulic elevator is often dependent on the height of your building.

A hydraulic elevator for a two-story building can cost between $4,000 – $10,000. For a four-story building, a hydraulic elevator can cost from $6,000 to $13,000. While for a five-story building, your estimated cost can go between $8,000 to $15,000.

As a professional elevator manufacturer, Dazen can install new hydraulic elevators for your building, or modernize or repair your existing hydraulic system, contact us today!