What are Traction Elevators?

Traction elevators are driven by alternating (AC) or direct current (DC) electric motors. The friction between the hoist steel ropes and the sheave is used in traction elevators to move the cab.

Further, traction elevators use a counterweight to offset the occupants’ and elevator cab’s weights so that the electric motor doesn’t have to move as much. Thus, making traction elevators much more energy and power efficient than hydraulic elevators.

Elevator technology has evolved over the years, but traction elevators have remained relevant in the building industry. The uniqueness of traction elevators makes them stand out, especially for mid to high-rise buildings. Hence, making traction elevators the commonest, the first choice of most people, and a worthwhile investment for building and facility owners. They can also be a worthwhile investment for your project.

Different Types of Traction Elevators

1. Geared Traction Elevator

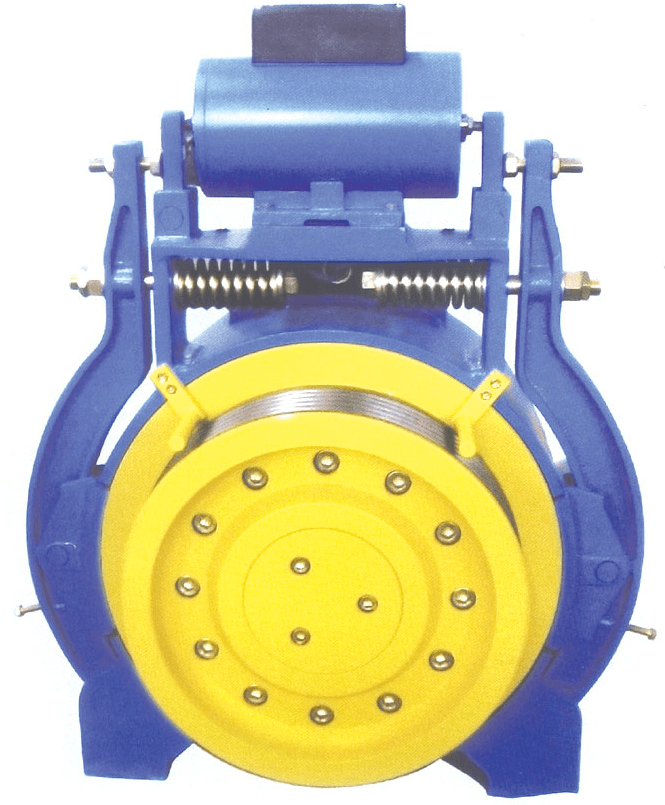

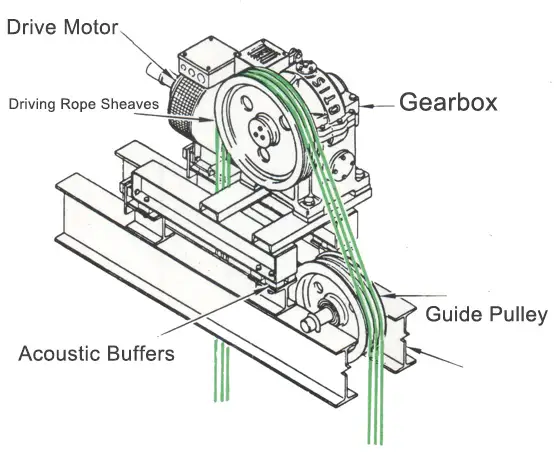

Geared traction elevators are unique with their simple structure and mature technology and are an excellent fit for freight and low-speed elevators. A typically geared traction elevator is usually propelled by an AC or DC electric motor. They also have gears between their electric motor and sheave, which drives the pulley and moves the steel ropes or flat steel belts.

The geared model has a peak speed of 500 ft./min and can carry loads as high as 13,000 kg. Although geared elevators have a slower speed than gearless ones, they require less powerful electric motors to drive the sheave and stand out for their average initial investment cost, maintenance cost and energy consumption.

That being said, there are significant concerns for geared traction elevators because they are designed to use both an asynchronous electric motor and a reduction mechanism and have a split design. Thus, there are concerns about low motor efficiency, large volume, low transmission efficiency, high energy consumption, high noise, and poor ride comfort.

2. Gearless Traction Elevator

80% of the traction elevators on the market are gearless, making them the most widely used. If you have a mid to high-rise building, then you don’t need to think twice about installing the gearless model because they can operate at very high speeds. Unlike the geared model, gearless elevators have their electric motor directly connected to the sheave.

The gearless model is usually driven by a synchronous motor and has a simple structure, reliable operation, small size, lightweight, high efficiency, low speed and high torque. Depending on the elevator model, configuration, and application, it can also reach between 2,000 to 4,000 ft./min.

Even so, if you want your elevator to move at a far slower speed like a typical hydraulic elevator, you need not worry because we can help you design a gearless elevator that moves at the rate of 100 ft./min.

A gearless elevator has high initial investment and moderate maintenance costs and is more energy efficient than the geared model. Therefore, they may be excellent for your tall and ultra-high buildings if you prioritize speed and energy efficiency.

3. Machine Room-Less (MRL) Traction Elevator

If your top priority is saving space in your low to mid-rise building, then the MRL traction elevator may be the best fit for you. MRL elevators are designed not to require a machine room, thus helping you save considerable space in the building where the elevator is installed. They also have speeds similar to the gearless model.

Apart from helping you save space in your building, the MRL model can also help you significantly reduce initial investment cost and installation time because the electric motors are mostly placed inside the elevator shaft. MRL elevators are energy efficient and do not use oil or lubricants, thus eliminating contamination and potential fire risks.

Further, despite the benefits you gain when installing MRL traction elevators, you must note that they can be louder in operation than elevators with machine rooms.

How Do Traction Elevators Work?

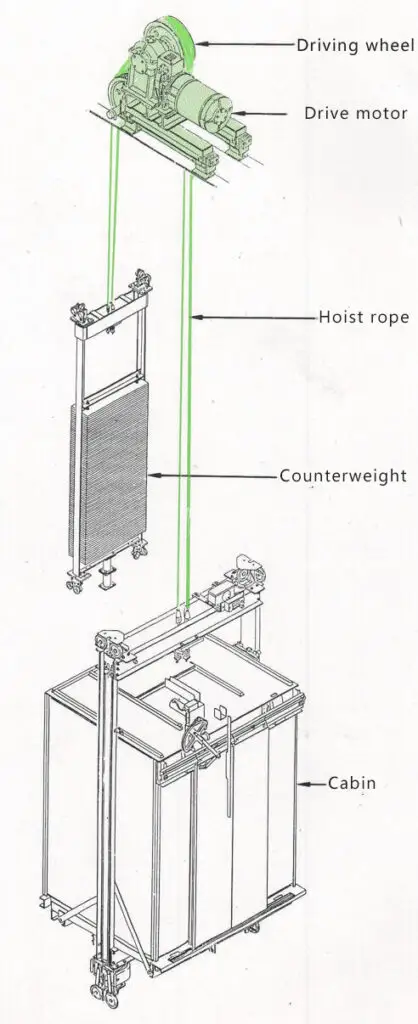

First, let’s look at a traction elevator’s components. A typical traction elevator has 4 parts which are:

- Cables or ropes

- Deeply grooved pulley (Sheave)

- Counterweight

- Electric motor

The working principle of traction and hydraulic elevators differs considerably. For instance, hydraulic elevators work on the principle that when a pump pushes oil into the cylinder, it also drives a piston which lifts the elevator cab. Likewise, for the cab to go down, a valve opens. Afterward, the oil flows back into the reservoir under the gravitational force of the cab.

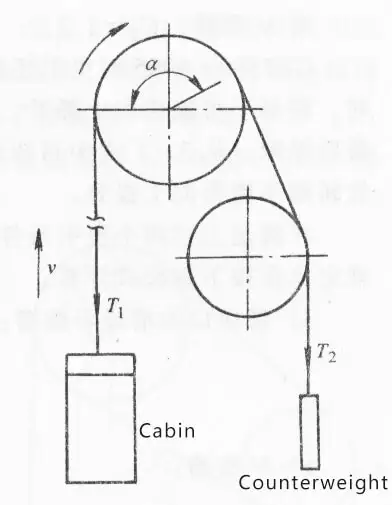

On the other hand, traction elevators work on a rope-and-pulley system that uses traction steel ropes or flat steel belts. Traction elevators are designed so that the cabs are usually pulled over a sheave (deeply grooved pulley) that is turned by an electric motor by the steel ropes or flat steel belts having a counterweight at their ends.

Further, the counterweight is essential to offset the weight of the elevator cab and occupants. Even so, there are instances where two elevators are built so that their cabs move synchronously in opposite directions and act as each other’s counterweight. Therefore, with the way traction elevators are designed, the motor doesn’t have to move as much weight, making it much more energy efficient than hydraulic elevators, which use a piece of hydraulic equipment.

What are the Benefits of Traction Elevators

- Traction Elevator Pros

- It offers a smoother and quieter ride

- Can travel a nearly unlimited number of floors

- Smaller electric motor size and control room requirements

- Accommodates front and rear openings in any configuration

- It has greater power and energy efficiency than hydraulic elevators

- Travels faster and covers longer vertical distances than hydraulic elevators

- It doesn’t require lubrication, thus eliminating the risk of oil contamination and potential fire risks

- The safety systems in a traction elevator are explicitly designed to prevent dead drops and injury resulting from mechanical failure or steel ropes or flat steel belts breaking

What’s The Disadvantage Of Traction Elevator?

- Limited cab weights and capacities

- More expensive to install and maintain than hydraulic elevators

- It takes longer to install, thereby adding an extra 4-6 weeks to the project schedule

- Crane is typically required, and there are structural building considerations because the top of the hoistway supports the elevator, and the building roof cannot be installed over the hoistway

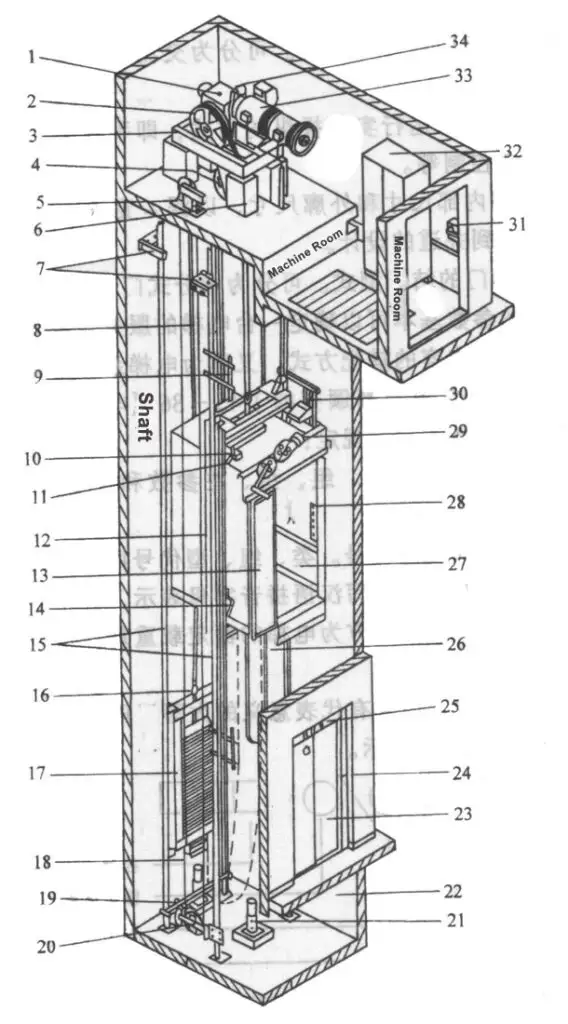

Traction Elevator Diagram

1.Reduction gearbox

2.Traction machine

3.Traction machine base

4.Guide sheave

5.Speed limiter

6.Machine base

7.Guide bracket

8.Rope

9.Switching iron

10.Terminal switch

11.Guide shoe

12.Lift frame

13.Lift door

14.Safety clamp

15.Guide rail

16.Rope head combination

17.Counterweight

18.Compensation chain

19.Compensation chain Guide wheel

20.Tensioning device

21.Buffer

22.Base

23.Floor door

24.Call box

25.Floor indication

26.Entourage cable

27.Lift wall

28.Maneuvering box

29.Door opener

30.Shaft sensor

31.Power switch

32.Control cabinet

33.Traction motor

34.Brake

Do You Need Help with a Traction Elevator?

We hope that this guide has been beneficial and that you found it useful in selecting a particular type of elevator.

We are an experienced elevator solution provider that can provide you with all types of traction elevators that can guarantee savings on initial investment and maintenance costs, installation space, and energy use.

Contact us to help you design traction elevators that meet your specific needs and requirements without sacrificing anything, and you can choose from various materials and accessories. So, whether you need an elevator for your low to high buildings, we have the expertise and experience you can trust.