What is Traction Elevator?

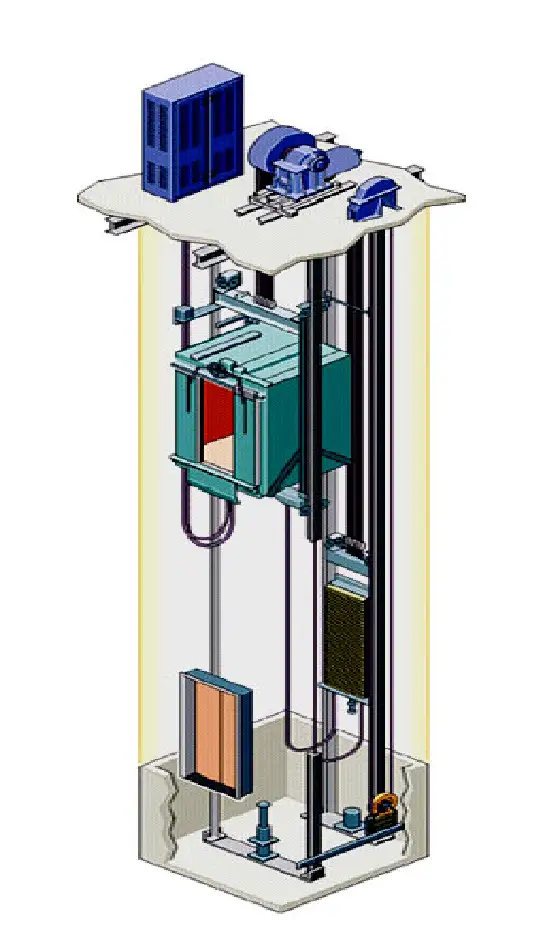

A traction elevator, also referred to as an electric elevator or cable-driven elevator, is a type of elevator that utilizes ropes or cables along with a motor-driven pulley system for vertical transportation of people or goods between floors in a building. This type of elevator is suitable for use in various building types and is recognized for its efficiency, speed, and versatility.

Working Principle

Traction elevator employs ropes or cables in conjunction with a motor-driven pulley system to facilitate the vertical movement of the elevator car. The ropes or cables are fastened to a pulley or sheave positioned at the top of the elevator shaft and are then connected to a motor-driven traction machine that regulates the elevator’s motion. When called to a floor, the traction machine activates the motor, prompting the ropes or cables to move and thereby transporting the elevator car in the intended direction. To descend, the traction machine reverses the motor, causing the ropes or cables to unwind from the pulley or sheave, facilitating the elevator car’s descent. The movement of the ropes or cables is meticulously controlled by the traction machine to ensure a smooth and safe ride between floors. Once the elevator car reaches the desired floor, the traction machine halts, and the ropes or cables hold the elevator car in position until a new destination is chosen.

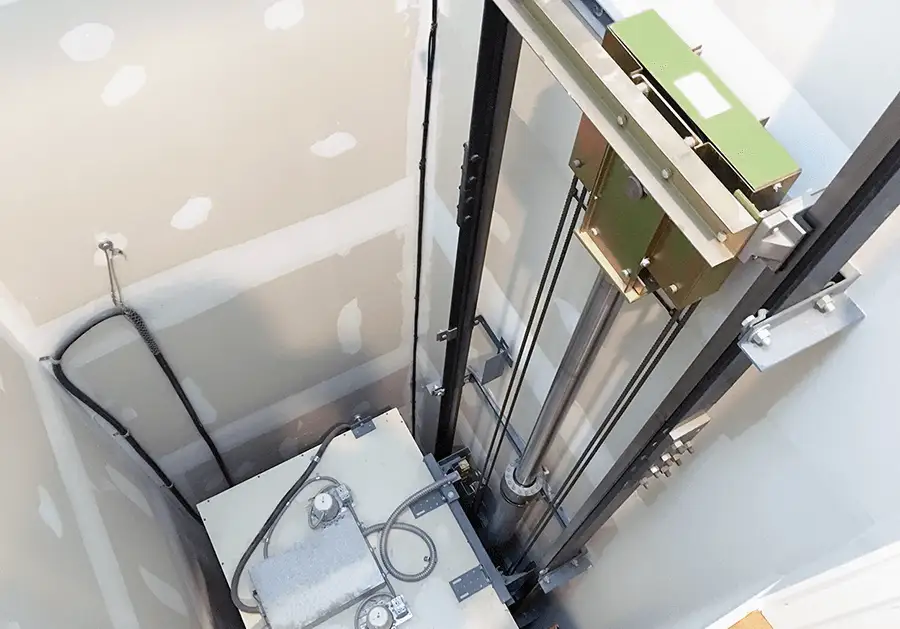

What is Hydraulic Elevator?

A hydraulic elevator is a form of vertical transportation that employs a hydraulic system to move individuals or objects between various levels of a building. This type of elevator is commonly utilized in buildings with fewer floors, such as low-rise to mid-rise structures, usually up to 7 levels.

Working Principle

A hydraulic elevator uses a mechanism that involves cylinders filled with fluid and a pump to facilitate the vertical movement of the elevator car. The elevator car is supported by a piston connected to the bottom of the car, which fits inside a cylinder filled with hydraulic fluid, typically oil. When the elevator is called to a floor, an electric pump pushes hydraulic fluid into the cylinder, causing the piston to move upwards and lift the elevator car. For the descent, the hydraulic fluid is released from the cylinder, allowing the elevator car to lower. The flow of hydraulic fluid is regulated by a valve operated by the elevator’s control system, ensuring smooth and safe movement between floors. Once the elevator car reaches the desired floor, the valve closes, and the hydraulic system maintains the elevator car in position until a new destination is selected.

Types of Traction Elevators

- Geared Traction Elevator: Utilize a gearbox and a motor to drive the elevator car through a hoist rope. They are commonly installed in medium to high-rise buildings and have a maximum weight capacity of 10,000 pounds. Geared traction elevators are praised for their smooth and quiet ride, and are often found in office buildings, hotels, and residential buildings.

- Gearless Traction Elevator: utilize a motor that is directly connected to the hoist rope, eliminating the need for a gearbox. This design enables higher speeds and weight capacities compared to geared traction elevators, with maximum weight capacities of up to 25,000 pounds. Gearless traction elevators are commonly used in tall buildings such as skyscrapers and offer a smooth and quiet ride.

- MRL Traction Elevator: Integrate the elevator equipment into the shaftway, eliminating the need for a separate machine room. This design saves space and reduces installation costs, making it a popular choice for modern buildings. MRL traction elevators are available in both geared and gearless versions.

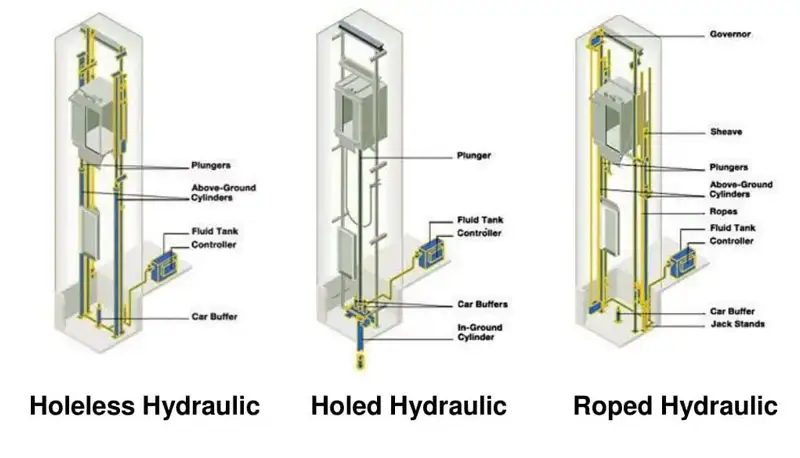

Types of Hydraulic Elevators

- In-Ground or Holed Hydraulic Elevator: It shares similarities with conventional hydraulic elevators, but differs in that they are installed below the elevator shaft, in a designated pit. This particular installation method makes them a favored choice for retrofitting older buildings that lack the space for an overhead machine room.

- Hole-Less Hydraulic Elevator: Utilize a telescoping piston system that eliminates the need for a separate cylinder and pit, resulting in a more space-efficient option that does not require excavation below the elevator shaft.

- Roped Hydraulic Elevator: Combine hydraulic and mechanical systems to vertically transport the elevator cab. They feature a piston and cylinder system, similar to conventional hydraulic elevators, but also utilize ropes and a sheave system to provide added support and stability.

Advantages of Traction Elevators

Faster Speed and Greater Travel Distance

Traction elevators can achieve higher travel speeds, with some models capable of speeds exceeding 500 feet per minute (fpm), allowing for quicker vertical transportation.

Smooth Ride Quality

Traction elevators are known for their smooth operation and high passenger comfort during rides.

Energy Efficiency

Modern traction elevators incorporate Variable Voltage Variable Frequency (VVVF) technology, which helps to reduce energy consumption and achieve energy-saving benefits.

Long Lifespan

Traction elevators experience lower component wear and have a longer service life compared to hydraulic elevators, resulting in increased durability and reliability.

Low Noise

Traction elevators are generally quieter than hydraulic elevators as they use a motor-driven pulley system instead of hydraulic pumps, resulting in reduced noise during operation.

Suitable for Buildings of All Heights

Traction elevators are versatile and can be installed in various types of buildings, including residential, commercial, and high-rise buildings, and can be customized to meet specific building requirements.

Disadvantages of Traction Elevators

Challenging Installation

Installing traction elevators can be more intricate compared to hydraulic elevators, as it involves the installation of ropes, cables, and counterweights.

Building-specific Requirements

Traction elevators have specific requirements for overhead and pit dimensions, which need to be taken into consideration during installation.

Advantages of Hydraulic Elevators

Superior for Transporting Heavy Loads

Hydraulic elevators are capable of carrying heavier weights than traction elevators due to their robust lifting capabilities.

Faster Installation: Hydraulic elevators have a simpler structure compared to other types of elevators, making installation and maintenance quicker and easier.

Cost-Effective

The simpler mechanical components of hydraulic elevators result in lower installation and maintenance costs, making them a more affordable choice for certain building types and budgets.

Machine Room-Less Option

Hydraulic elevators can be configured as machine room-less (MRL), where the hydraulic pump and other components are housed within the elevator shaft or in a nearby cabinet. This eliminates the need for a separate machine room, providing additional space-saving benefits.

Disadvantages of Hydraulic Elevators

Unsuitable for High-Rise Buildings

Hydraulic elevators are less efficient at greater heights, making them less suitable for high-rise buildings, typically limited to buildings up to 7 stories.

Speed Limitations

Hydraulic elevators have speed limitations, usually up to 150 feet per minute (fpm), which may not be sufficient for certain high-rise or high-traffic buildings.

Lower Efficiency

Hydraulic elevators require more power to operate compared to traction elevators due to the need to generate enough pressure with the hydraulic pump. This can result in higher energy consumption and operating costs over time.

Slightly Noisier

Hydraulic elevators may generate more noise during operation compared to traction elevators, as the hydraulic pump and motor can produce some noise.

Which is The Best For Your Building?

In conclusion, hydraulic elevators have advantages in terms of safety and load capacity, but they have certain shortcomings in terms of speed, space occupation and environmental protection.

Traction elevators have advantages in terms of speed, smoothness of operation, and space occupation, but they have certain shortcomings in terms of installation cost, maintenance cost, and load capacity.

When deciding between traction and hydraulic elevators, it’s important to carefully consider the specific needs of your building. Consulting with a qualified elevator expert can help ensure that you make the best decision for your building.

At Dazen, we specialize in providing the best traction elevator systems tailored to your building’s specific needs. Our team of experts will work with you to determine the best type of elevator for your building, considering factors such as building height, passenger volume, available space, and budget. Contact us today to learn more about our elevator systems and how we can help you find the perfect elevator for your building.