What is an Escalator?

An escalator, also known as an electric escalator or moving staircase, is a transportation device that conveys pedestrians using a continuous belt system. Typically installed at an incline, escalators transport individuals from one end to the other effortlessly. Passengers stand on the moving steps at the entrance of the escalator, and the steps remain level throughout the journey. For passenger safety and support, escalators are equipped with handrails on both sides that move in sync with the steps, allowing passengers to hold onto them while riding.

How Does an Escalator Work?

An escalator is a mechanical device used to transport people between different floors of a building. It consists of a series of steps or treads that move in a continuous loop, allowing passengers to step on or off as needed. Let’s delve into the workings of an escalator:

Step Chain: The steps are linked together by a looped metal chain that forms an unending belt. This chain is driven by an electric motor located at the top or bottom of the escalator.

Motor and Drive System: The motor powers the escalator and is typically an electric motor located in a machine room. It provides the necessary energy to move the steps in a continuous motion. The motor’s rotational motion is transmitted to the step chain through a series of gears and pulleys.

Handrail Drive System: In addition to the steps, escalators also feature handrails on both sides. The handrails move at the same speed as the steps to provide support and stability for passengers. The handrail drive system consists of a separate motor and drive mechanism specifically designed to move the handrails.

Tracks and Guides: The steps and handrails run on tracks and guides to ensure smooth and precise movement. These tracks and guides are typically made of metal and are designed to keep the steps and handrails in their proper positions as they travel along the escalator.

Balustrade: The balustrade is the structure that encloses the sides of the escalator. It provides a protective barrier for passengers and prevents them from falling off the sides. The balustrade often incorporates the handrail system.

Safety Features: Escalators are equipped with various safety features to ensure passenger safety. These include comb plates at the entrance and exit points, which help prevent tripping hazards, and skirt brushes that minimize the risk of entrapment between the steps and the balustrade.

Sensors and Controls: Escalators have sensors and control systems that monitor their operation and detect any anomalies or obstructions. For example, if an object gets caught in the escalator, sensors will detect the issue and trigger an emergency stop to prevent accidents.

When the escalator is powered on, the steps and handrails move in a synchronized manner. As one end of the chain moves over the top of the escalator, the steps are lifted and positioned horizontally at the entrance. They then move in a diagonal path, transporting passengers smoothly between different levels of a building. Finally, the steps reach the bottom of the escalator, dip down, and loop back to the top to repeat the cycle.

It’s worth noting that while the basic principles of escalator operation remain the same, there may be variations in design and configuration depending on the manufacturer and specific installation requirements.

How Much Does an Escalator Cost?

The cost of an escalator can vary significantly depending on various factors, such as its length, rise height, running speed, step width, finishes, etc. The price range for an escalator falls between $15,000 and $25,000, luxury or high-end models might cost even more. If installation is included, the cost of an escalator can range from $20,000 to $30,000.

For a precise and up-to-date estimate, it is recommended to consult escalator manufacturers or suppliers, as prices can change over time and may differ based on specific project needs.

Factors Influencing Escalator Price

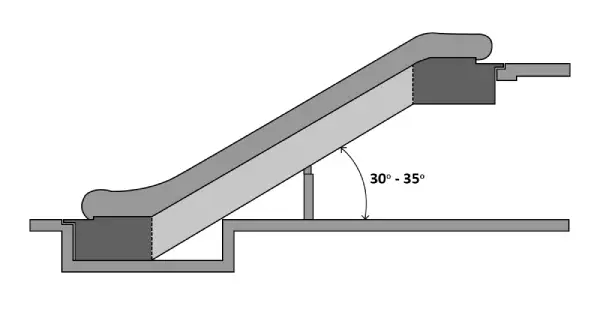

1) Inclination Angles

Inclination angles for commercial escalators are available in options of 30 and 35 degrees. This angle strikes a balance between providing a smooth and comfortable ride for users and maintaining efficient operation.

Airports, train stations, and subway stations often utilize heavy-duty escalators due to their capacity to handle a large volume of people. These escalators can be customized to suit specific requirements, including the option of two angles: 27.3° and 23.2°. The flexibility in angle selection allows for optimal integration into various infrastructure layouts, ensuring smooth and efficient passenger movement.

2) Step Width

The most common widths for escalator step are 24 inches (600mm), 32 inches (800mm), and 40 inches (1000mm). The wider the step, the higher the cost.

3) Rise Height (Vertical Rise)

The height of an escalator often corresponds to the vertical distance it needs to cover. Higher rise heights result in longer escalators, requiring longer escalator tracks and taller trusses, which can increase the overall cost.

Also, taller escalators may require additional structural support to ensure stability and safety. This could involve reinforcing the building’s framework, installing heavier materials, or using more robust engineering solutions. These factors can contribute to increased costs.

4) Escalator Length (Horizontal Span)

The longer the length of the escalator, the higher the price. The length of an escalator can have a significant impact on its price, as it directly affects the materials required, manufacturing complexity, installation process, and overall engineering considerations. It should be noted that the maximum length of the escalator should not exceed 50m.

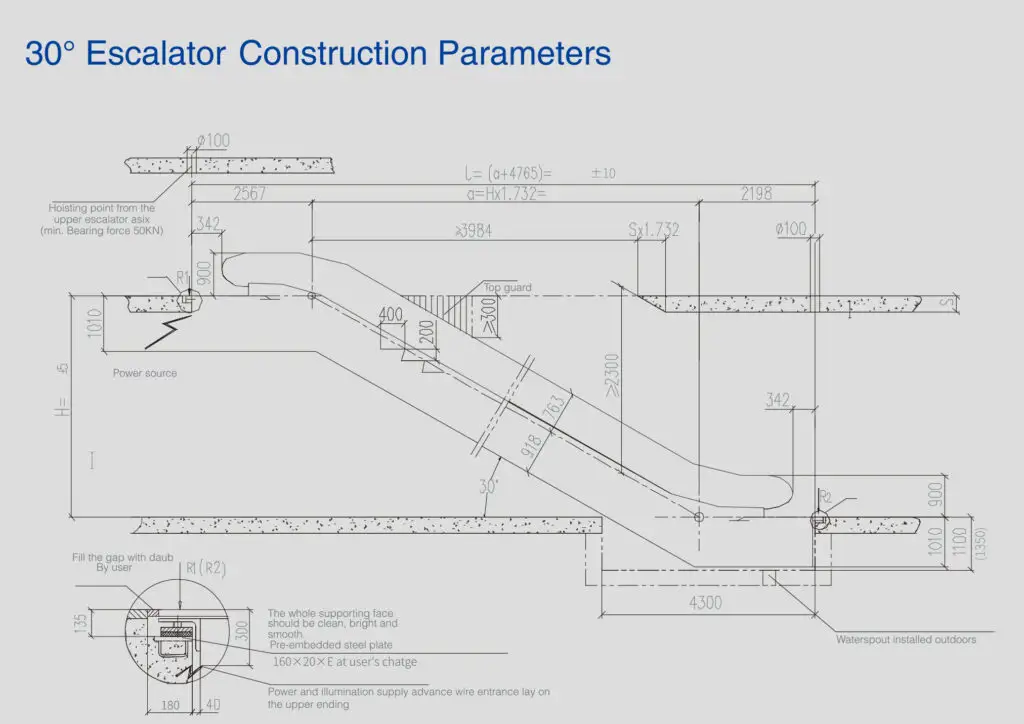

● How to Calculate Escalator Length

When the angle is 35°:

Indoor Escalator L = Escalator height(m) * 1.428 + 4.905m

Outdoor Escalator L = Escalator height(m) * 1.428 + 5.105m

When the angle is 30°:

Indoor Escalator L = Escalator height (m)* 1.732 + 4.765 m

Outdoor Escalator L = Escalator height(m) * 1.732 + 4.965m

For example, when the rise height is 5 meters and the inclination angle is 35 degrees, the length of the indoor escalator can be calculated as:

L = 5m * 1.428 + 4.905 = 12.045 meters

5) Speed

When it comes to escalators, speed refers to the travel velocity of the moving steps. escalators generally have a speed of 0.50m/s, 0.65m/s, 0.75m/s, and 0.90m/s (approximately 1.6 to 3.3 feet per second). Normally 0.5m/s (1.6 feet per second). The faster the speed, the more expensive the price.

6) Horizontal Steps

The number of steps on the horizontal plane, known as the tread, can impact the price of an escalator. The tread refers to the flat portion of each step where passengers stand while being transported. Typically, there are two steps on the horizontal plane and the cost increases for escalators with more than two steps.

The inclusion of each additional horizontal step results in an approximate increase in the cost of 1600 USD.

7) Indoor or Outdoor Installation

Escalator installations are categorized as either indoor or outdoor installations. Outdoor escalators require special consideration for protection against harsh weather conditions and corrosion due to their installation in open areas. They need to be waterproof, and resistant to sunlight, oil, frost, and other weather elements. This necessitates the use of materials and coatings with high corrosion resistance and additional safety measures. As a result, outdoor escalators are typically more expensive than indoor escalators, with an average price difference of around $5,000.

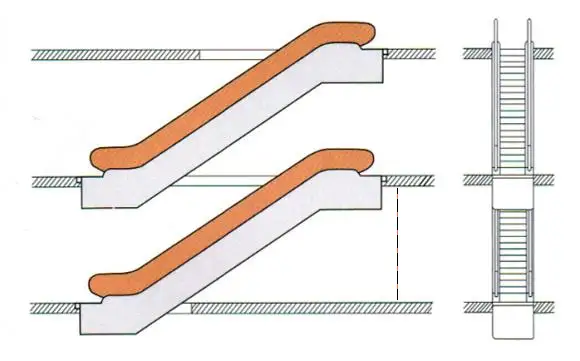

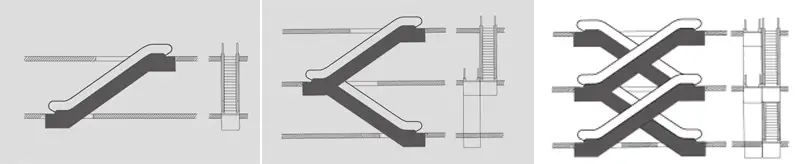

8) Multiple Parallel or Crisscross

The design and configuration of escalators can vary depending on the specific requirements of a building or installation. Two common types of escalator configurations are multiple parallel escalators and crisscross escalators.

For installations of two or more escalators, paralleling is less expensive than crossover installations because it saves one face of upholstery.

9) Additional Decorations

Indeed, various additional decorations and features can impact the price of an escalator. Such as handrail strip lighting, skirt lighting, handrail strip color and material, and step material.

10) Location

The location of your home and accessibility for the installation team can also affect the price. Remote or challenging locations may involve additional logistics and transportation costs.

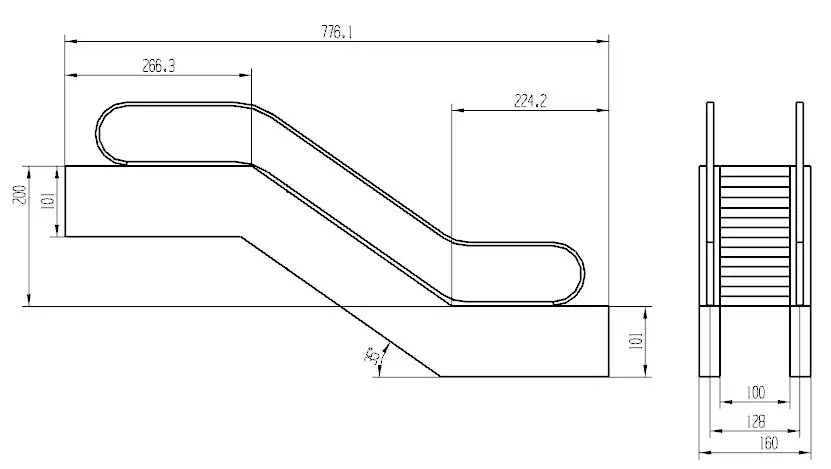

Escalator Dimensions

Escalator dimensions can vary depending on the specific model and manufacturer. However, here are some typical escalator dimensions for a standard commercial or public-use escalator:

• Width: Escalators usually come in three common widths: 24 inches (600mm), 32 inches (800mm) and 40 inches (1000mm)

• Length: The length of an escalator can vary significantly based on the building’s requirements and the available space. They can range from around 20 feet (6 meters) to over 60 feet (18 meters) or even longer. Maximum length cannot exceed 50m.

• Rise/Vertical Height: The rise, also known as the vertical height or elevation, is the total distance between the upper and lower landings. It can vary but is typically around 20 to 30 feet (6 to 9 meters), and a maximum of 23 meters.

These dimensions are general guidelines, and actual specifications can vary depending on the specific requirements of the building, the manufacturer, and local regulations. When installing or designing escalators, it’s crucial to comply with safety and accessibility standards to ensure the well-being of users.

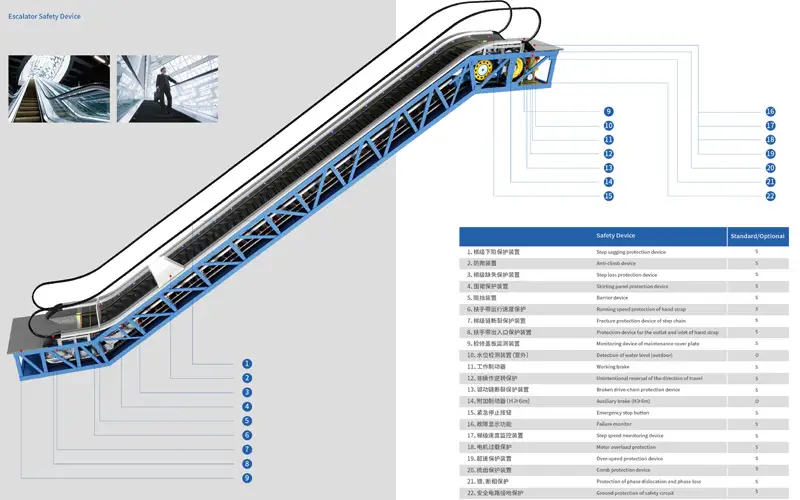

What are the Escalators’ Safety Features?

Escalators are equipped with several safety features to ensure the well-being of passengers. Here are some common escalator safety features:

• Handrails: Escalators have handrails running parallel to the steps. Passengers are encouraged to hold onto the handrail while riding the escalator to maintain balance and stability.

• Step Sensors: Escalators are equipped with sensors that detect the presence of a passenger on a step. These sensors prevent the escalator from moving if there is an object or obstruction on the steps, reducing the risk of accidents.

• Skirt Brushes: Escalators have skirt brushes installed along the sides. These brushes help prevent clothing, loose items, or body parts from getting caught between the steps and the sidewalls, reducing the risk of entrapment.

• Emergency Stop Buttons: Located at the top and bottom of escalators, emergency stop buttons allow anyone to immediately halt the escalator’s movement in case of an emergency or if an unsafe condition is observed.

• Safety Comb Plates: At the top and bottom of the escalator, comb plates are installed to ensure a smooth transition between the stationary floor and the moving steps. These plates have teeth-like structures that prevent passengers from tripping or stumbling during entry or exit.

• Balustrades and Skirting: Escalators have balustrades on both sides to provide a physical barrier between the moving steps and the surrounding area, reducing the risk of accidental falls. Skirting panels cover the sides and bottom of the escalator, preventing access to the undercarriage.

• Speed Sensors and Overload Protection: Escalators are equipped with speed sensors to detect any abnormal increase or decrease in speed. If an issue is detected, the escalator is designed to automatically stop or slow down. Additionally, escalators have overload protection mechanisms that monitor weight limits and prevent operation if exceeded.

• Emergency Lighting and Alarms: In the event of a power failure or emergency, escalators are equipped with emergency lighting to ensure visibility and guide passengers safely. Audible alarms are also present to alert passengers and staff in case of an emergency.

Escalator Installation and Maintenance

Installing and maintaining escalators require careful planning, adherence to safety regulations, and periodic inspections to ensure proper functioning and safety for users. Here are the key aspects of escalator installation and maintenance:

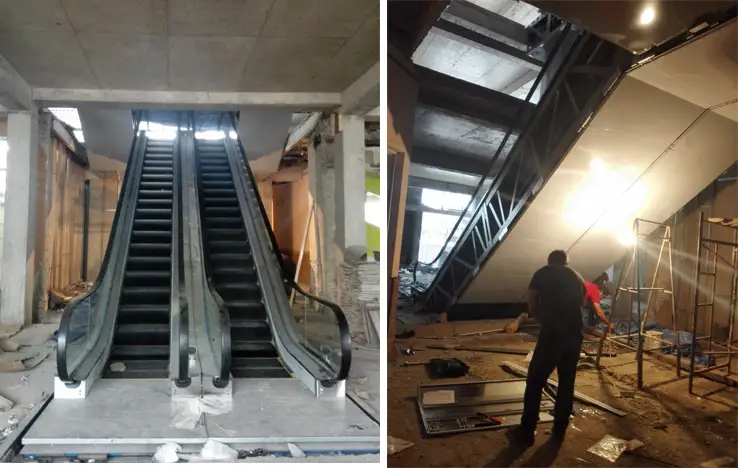

Escalator Installation

• Site Assessment: Before installation, a thorough site assessment is conducted to determine the best location for the escalator, considering factors like foot traffic, available space, and building design.

• Permits and Regulations: Obtain all necessary permits and comply with building codes, safety regulations, and standards set by local authorities and escalator manufacturers.

• Planning and Design: Work with experienced escalator manufacturers or contractors to design a system that fits the building’s requirements and passenger flow.

• Preparation: Ensure that the installation site is ready, including proper structural support, power supply, and necessary utilities.

• Delivery and Assembly: The escalator components are delivered to the site, and the installation process begins, including assembling the truss structure, steps, handrails, and safety features.

• Testing and Inspection: Conduct thorough testing and inspection to ensure the escalator functions safely and correctly.

Escalator Maintenance

• Regular Inspections: Schedule regular inspections by qualified technicians to identify and address potential issues before they become major problems. The frequency of inspections may vary depending on escalator usage and local regulations.

• Cleaning: Regular cleaning of escalator components, such as steps, handrails, and comb plates, to maintain hygiene and prevent debris buildup.

• Lubrication: Proper lubrication of moving parts is essential to reduce friction and wear and tear, ensuring smooth and efficient operation.

• Component Replacement: As escalators age, certain components may need replacement due to wear or obsolescence.

• Emergency Stop Tests: Periodically conduct emergency stop tests to verify the escalator’s safety features are functioning correctly.

• Safety Checks: Verify that all safety features, such as sensors, safety brushes, and skirts, are in good working order.

• Training for Staff: Train building maintenance staff to recognize early signs of potential issues and how to respond in emergencies.

Remember that escalator installation and maintenance should be carried out by experienced and certified professionals to ensure compliance with safety standards and the efficient operation of these complex machines.

Conclusion

Discover the Future of Vertical Transportation with Dazen Escalators!

If you are seeking a reliable, efficient, and aesthetically pleasing solution for vertical transportation, look no further than Dazen Escalators. Let us elevate your commercial space to new heights with our world-class escalator systems.

Why Choose Dazen Escalators?

Advanced Technology: Dazen Escalators harness the latest technological advancements to guarantee a smooth, silent, and energy-efficient ride.

Uncompromising Safety: Safety is our top priority, and every Dazen Escalator undergoes rigorous testing and adheres to the strictest safety standards.

Customization Options: We understand that every space has unique requirements, and that’s why Dazen Escalators offer a wide range of customization options. From various designs, materials, and finishes to different sizes and capacities, we can tailor our escalators to suit your specific needs and complement your architectural vision.

Expert Support: Our team of dedicated professionals is always ready to assist you throughout the process, from initial consultation to installation and beyond.

Join the Dazen family today and experience the future of vertical transportation! Our escalators will not only move people but also elevate your business to new levels of success and customer satisfaction. Choose Dazen Escalators and move with confidence!