What’s an Elevator Machine Room?

The elevator machine room is the control house of your elevator. This specialized area keeps mechanical and electrical components to ensure smooth and secure operation. Its access is restricted to authorized personnel as it comprises sensitive equipment. Any disturbance in the operations can significantly damage the elevator and put passengers in danger.

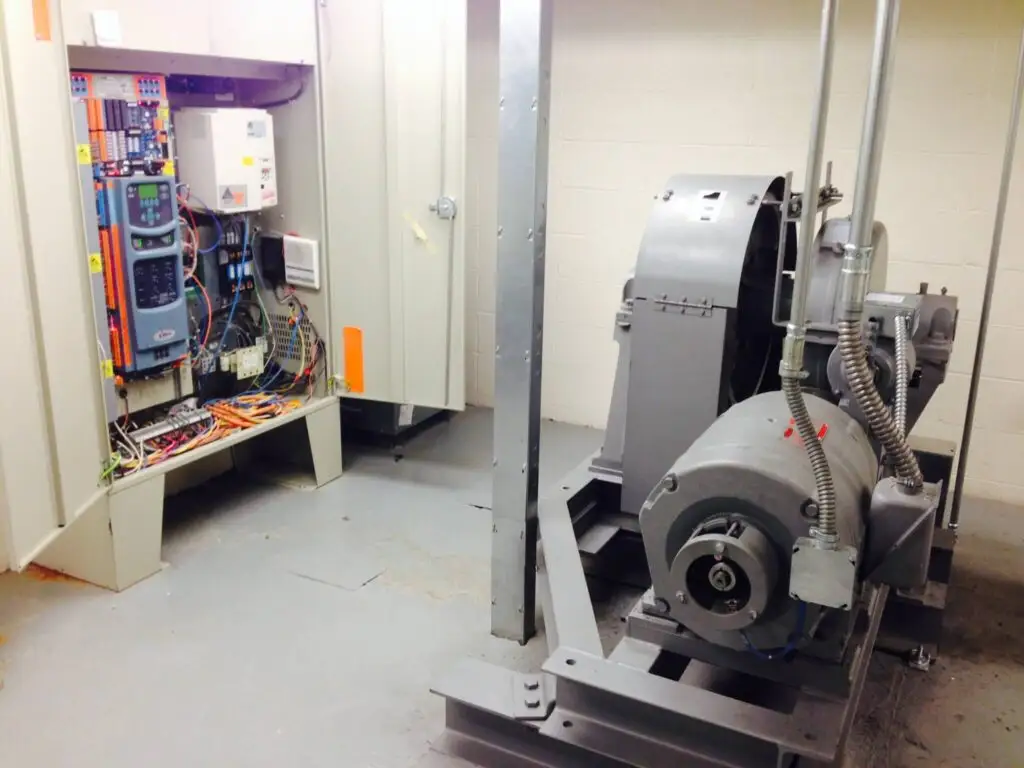

The room has a controller, motor, disconnect switches, and other auxiliary components. The elevator controller is the most prominent component of the machine room and controls the operations of the elevator motor. It monitors the passenger’s call and sends the elevator to your requested floor.

The motor is the elevator drive unit that lifts and lowers the elevator cabin. The elevator machine room also houses two disconnect switches. One controls the unit’s power, and the other controls the elevator’s emergency lights. An elevator machine room also houses emergency brakes and limit switches. These crucial components ensure the safety of passengers and prevent accidents.

What Is the Function of the Elevator Machine Room?

The elevator machine room controls how the elevator works. It holds the machines and electrical systems that move the elevator, stop it safely, and connect it to the buttons inside and on each floor.

In traction elevators, the machine room manages the motor, gears, and brakes that lift and lower the car with steel ropes. In hydraulic elevators, it powers the pump that moves the car up and uses valves to bring it down smoothly.

This room makes sure the elevator runs safely and efficiently. It controls the speed, stops the car at the right floor, and keeps it steady during use. It’s also where technicians check and fix any problems.

Where is the Machine Room Located?

In a traction elevator, the elevator machine room is often located above the elevator shaft or in a nearby space.

In hydraulic elevators, it usually stays next to the shaft, builders place it in the basement or ground level near the elevator in some cases.

This brings us to the question: What is the difference between a traction elevator machine room and a hydraulic elevator machine room?

What is a Traction Elevator Machine Room?

Traction elevators are a vertical transport system that uses motor-driven cables and counterweights. These high-speed elevators need a machine room to accommodate the essential equipment in a separate area. A traction elevator machine room is necessary for low to high-rise buildings. With DAZEN Elevator, you can conveniently install a traction elevator machine room in your building. You can observe the following components in it:

Elevator Traction Machine

This crucial component is responsible for lifting and lowering the elevator. It consists of a motor that operates the sheave. The sheave is connected to hoist cables. Hoist cables wind or unwind as the motor operates.

Control Panel

The control panel is the control system for managing the elevator’s movement. It responds to passengers’ calls and guarantees safe travel. Any damage to the control panel can lead to the elevator malfunctioning.

Counterweight

Counterweights in your elevator balance the weight of the car and passengers. Accurate counterweights are necessary to maintain the required speed and torque. It ensures the proper functioning of the elevator and minimizes energy consumption.

Safety Equipment

When discussing a high-speed elevator, how can we ignore safety gear? Your traction elevator machine room contains safety equipment. It includes brake shoes, contactors, limit switches, etc. These gears work together to secure your elevator’s operation in case of any emergency or power off.

Backup Power System

The emergency power supply is a lifesaver for your elevator. Just imagine you are in the middle of the ride, and there is a sudden power cut! It’s definitely a nightmare. Many traction machine rooms have backup power systems to avoid such a situation. It comprises power generators or batteries.

What is a Hydraulic Elevator Machine Room?

Unlike traction elevators, hydraulic elevators require a different machine room setup. You should install a hydraulic elevator if you don’t have a high building. This reliable system lets you conveniently transport in your low or mid-rise home or office building. Here is the equipment in a hydraulic elevator machine room:

Hydraulic Pump Unit

This crucial component includes a hydraulic pump, an electric motor, and a reservoir. It drives and stops the elevator. The electric motor powers the hydraulic pump to raise and lower the elevator by converting electric energy into mechanical energy. The oil reservoir in the machine room maintains the temperature of the hydraulic fluid for smooth functioning.

Control Valves

Control valves are another key component of hydraulic elevators that reside in your machine room. These valves control the flow of hydraulic fluid in the hydraulic cylinder. They control the speed as well as the direction of your elevator.

Controller

The hydraulic elevator controller is the brain of the elevator system. It is connected to a power source and receives signals from safety switches, valves, and other components. It controls the operations of the elevator. In addition, it manages the level of the car on each floor of the building.

Safety Gears

Like traction elevator machine rooms, hydraulic elevator machine rooms also have safety gears for passengers’ safety. It comprises emergency brakes, overspeed governors, and buffers. These components cushion the elevator in emergency situations.

Backup Power Supply

Some hydraulic elevator machine rooms have a backup power supply. It is necessary to prevent the elevator car from getting stuck in case of power failures. The backup power supply consists of a battery or power generator which supplies power to the motor and other components.

This video shows the location of the hydraulic elevator’s machine room.

Do All Elevators Require a Machine Room?

Though machine rooms make it convenient to locate controllers, drive units, and other support components safely, they take up a lot of space. Dedicating an entire room for a single elevator is often not feasible for all buildings. Many people ask, “Is an elevator machine room compulsory for my elevator?” Well, the answer is “No”.

Thanks to the advanced solutions that eliminate the need for a machine room. With machine-room-less elevators, you don’t have to stress about a separate machine room. Let me introduce you to machine-room-less elevators.

In modern architecture, where every square foot counts, machine-room-less elevators are a great choice. Unlike traditional elevators, machine-room-less elevators accommodate the necessary machinery above the shaft or some adjacent space. With its space-effective design, you can dedicate your room to other purposes. Installing miniaturing technologies within your machine-room-less elevator can make it more efficient.

In addition to saving space, this model also saves electricity charges using the regenerative drive system. This drive converts braking energy into electric energy, contributing to energy savings.

Using gearless traction machines also makes it noise-free. Moreover, its compact design requires less maintenance and repair. This sustainable solution offers you a fantastic opportunity to boost the productivity of your building.

The equipment for the machine room-less elevator is installed directly on the hoistway’s side wall.

Elevator Machine Room Requirements

Before setting up an elevator machine room in your building, you should know the requirements and regulations. If you don’t know about these standards and requirements, don’t worry. I can help you out! Here are some of the basic requirements for an elevator machine room:

Temperature

Temperature can significantly affect the components in your machine room. According to UCSC Elevator Standards, the temperature of your machine room should be in the range of 60 to 80 degrees Fahrenheit. This temperature range ensures the safety of technicians as well as your elevator.

Lighting and Ventilation

Your elevator room should be well-ventilated and well-lit. Proper lighting provides a safe and secure working environment for the technicians. You should also install emergency lights to prevent damage in case of power failures. According to UCSC Elevator Standards, a machine room must have fluorescent lights. Moreover, the position of the lighting should be in such a way that it will not create any shadow. According to the 2015 International Building Code (IBC), BASIC, your elevator machine room should have an independent ventilation or air-conditioning system to prevent overheating.

Fire-Extinguisher

Elevator machine rooms are susceptible to fires due to the presence of electrical and combustible materials. Therefore, a fire extinguisher is a must-have in your machine room. According to UCSC Elevator Standards, you must have a 15-pound class B-C fire extinguisher in your elevator machine room.

Plumbing System

For safety, any plumbing system should be strictly avoided in your elevator machine room. According to the 2015 International Building Code (IBC), BASIC, you shouldn’t locate any plumbing system in a machine room as it can be hazardous for the technicians and other personnel.

Paint

The color and texture of pain are other considerable factors for your machine room. According to the General Requirements of the University of Michigan, use light gray gloss oil-based paint for the floor. Use white semi-gloss latex paint for the ceiling and walls of the machine room.

Access

As per the 2015 International Building Code (IBC), BASIC, authorized personnel should provide an approved means to access the machine room. It is necessary to prevent any unauthorized access to the machine room. You can install self-locking doors to avoid unauthorized access.

Noise Control

Controlling noise is also necessary in the machine room as it can disturb the occupants. You should use soundproof material for constructing the walls of the machine room. Instal Sound transmission class (STC) of a minimum of 25 to prevent noise transfer to adjacent areas.

Electrical Requirements

Electric requirements vary depending on the type of elevator system. However, most elevators require two circuits. One is to operate the main disconnect switch, and the other is to power your elevator.

Elevator Machine Room Location

If you are confused about the elevator machine room location, you are not alone. Many building owners get perplexed when it comes to the machine room location. Well! There is not any restricted spot for it. You can construct your machine room in any place that you desire. However, locating it adjacent to the hoistway on the top floor is best.

According to the General Requirements of the University of Michigan, you should locate your machine room in the basement, overhead, or adjacent to the hoistway if you have a traction or hydraulic elevator.

What Size Machine Room is Required for an Elevator?

The elevator machine room is a vital aspect of establishing a secure working environment for technicians and engineers. Accommodating controllers, motors, backup power supplies, and other auxiliary gears in the machine room requires sufficient headroom. If you have little space with insufficient height, it can lead to various operational issues.

For example, the California Department of industrial Relations, your machine room should be at least7 feet high. Keep the height of your machine room more than 8 feet to maintain sufficient lighting andventilation.

There are three most stringent standards for elevator machine room dimensions, which are American Standard ASME A17.1, European Standard EN81-20, and Chinese Standard GB 7588-2003.

ASME A17.1

- Machine room height: min. 2.1 meters

- Access space: min. 0.9 meters around the equipment

- Door width: min. 0.76 meters

- Door height: min. 2.0 meters

EN 81-20 and GB 7588-2003

- Machine room height: min. 2.0 meters

- Access space: min. 0.5 meters around the equipment

- Door width: min. 0.6 meters

- Door height: min. 1.8 meters

If you are planning an elevator installation, it’s best to consult with elevator manufacturers like Dazen to determine the exact machine room size and layout for your specific needs.

We are also very good at non-standard projects, for example, we can provide the perfect solution for a machine room with a height of only 1.5m.

Frequently Asked Questions

1. Are Elevator Machine Rooms Required to Be Fire Rated?

Yes, most building codes require elevator machine rooms to have fire-rated walls, doors, and ceilings. Typically, these rooms must meet a one- or two-hour fire rating to ensure safety and prevent fire from spreading to or from the room.

2. Who Can Enter the Elevator Machine Room?

Only authorized personnel, such as certified elevator technicians, building maintenance staff, or emergency responders, are allowed to enter the elevator machine room. Restricted access ensures safety and prevents tampering or damage to critical equipment.

3. How to Cool the Elevator Machine Room?

You can cool the elevator machine room using ventilation systems, air conditioning units, or heat-extraction fans. Maintaining a stable temperature is essential to prevent overheating of sensitive machinery like motors, controllers, and electrical panels.

4. Does the Elevator Machine Room Need Maintenance?

Yes, regular maintenance is essential. Certified technicians inspect and service the motors, control panels, brakes, and safety systems to ensure the elevator operates efficiently and safely. Neglecting maintenance can lead to equipment failure and safety hazards.

5. Is There Any Sign in the Elevator Machine Room?

Yes, an elevator machine room sign is a safety notice placed at eye level near the machine room to prevent unauthorized entry and enhance safety. The standard wording includes: “ELEVATOR MACHINE ROOM- AUTHORIZED PERONNEL ONLY.”

Conclusion

Your elevator machine room is one of the most integral elements of your elevator system. A secure and well-maintained machine room provides a smooth elevator experience. DAZEN Elevator can help you create a safe and convenient environment for vertical transport. It provides elevator machine rooms as well as machine-room-less elevators.

If you want to install a machine room with all the components, DAZEN Elevator is the best choice for you. It offers the best elevators and machine rooms for homes as well as commercial buildings. Contact us now!