This article introduces the principle, structure, classification, advantages and disadvantages of escalators, installation procedures and operation methods to deepen your knowledge of escalators.

10 Types of Escalators

1. Moving walkways

2. Parallel Escalator

3. Stairway escalators

4. Belt-type escalators

5. Curved escalators

6. Wheelchair-accessible Escalator

7. Step Type Escalator

8. Crisscross Escalator

9. Multi-story escalators

10. Outdoor escalators

Moving Walkways

A moving walkway or sidewalk is a conveyor transport system that automatically carries pedestrians. Moving walkways are often installed in pairs for each direction to allow inter-terminal pedestrian travel. They may be used in airports, stadiums, and other large venues where crowds of people want to move in a specific direction.

Moving walkways work by the same basic principle as a conveyor belt: they move at an angle to the ground with little friction. This causes the user less friction from the floor than simply walking on it. The result is a smooth ride without spending energy pushing off the ground.

Moving walkways are usually equipped with handrails for safety reasons. In some cases, the moving walkway is equipped with a rubberized surface that provides traction for shoes with poor traction on hard surfaces (for example, high heels). Modern moving walkways can operate at speeds up to 8 km/h (5 mph), although this speed is typically reserved for large crowds such as those found in airports; smaller groups or individuals will typically travel significantly slower due to their lack of momentum and inability to accommodate multiple people trying to pass each other at once.

Parallel Escalator

A parallel escalator is an escalator that is side by side with another. The two escalators move in the same direction and at the same speed. This escalator increases capacity, especially in crowded areas like shopping malls or train stations.

The parallel escalator has a few advantages over traditional escalators:

It can transport more people per unit of time than a straight up-and-down escalator because it has twice as many steps, which are wider than those on a straight up-and-down escalator.

It can carry more weight because each step can be wider and deeper than those on an up-and-down escalator.

It uses less space than two straight up-and-down escalators because it doesn’t require any room for moving sideways before turning back down again.

Stairway Escalators

Stairway escalators are the oldest type of escalator, and they’re still used in many places. They’re built into a staircase so you can go up or down like a regular staircase. They’re also called inclined stairway escalators or inclined moving stairs.

They’re especially good for areas where space is limited, like airports and train stations, because they don’t take up much space.

Belt-Type Escalators

These are the most common types of escalators. The steps are arranged in a rectangular shape, with the outer edges of each step slightly curved. This design allows passengers to stand safely on both sides of the belt. The steps have holes through which the cables run from one end to another and are connected to motors at each end of the escalator.

A typical belt-type escalator has two sets of parallel tracks that run along its length, with a pair of wheels on each track moving up and down as it travels along them. These wheels move in opposite directions for safety reasons: One set moves forward when going up and backward when going down, while the other set does the opposite. They are connected by guide rails at either end to remain aligned.

Curved Escalators

The curved escalator is a unique and eye-catching feature in many shopping centers and office buildings. A curved escalator is a moving walkway that is curved in the middle. These escalators are usually found in airports, malls, department stores and other public places.

The advantage of curved escalators is that they allow for much more efficient use of space than straight escalators. For example, a curved escalator can achieve the same vertical travel with less floor space than a straight one. This is because the radius of the curve allows for an arc longer than the arc created by a straight escalator.

Curved escalators also have some disadvantages:

They are expensive to install

They require more maintenance than straight escalators

They are not as safe as straight escalators

Wheelchair-Accessible Escalator

Wheelchair-accessible escalators are designed to accommodate wheelchairs and other mobility devices, including walkers, crutches and canes. They are located in high-traffic areas of a facility such as an airport or train station.

Wheelchair-accessible escalators have two sets of steps that alternate in direction as they move up or down. This allows passengers using wheelchairs or other mobility devices to move independently up or down the escalator. The steps are wider than standard steps to accommodate larger wheelchairs and scooters. A platform is provided at the top and bottom of the escalator so passengers can safely change directions without stepping off onto the floor.

Step Type Escalator

Step-type escalators are stair-like devices that transport passengers up or down a vertical distance. They are also referred to as stepped conveyors or simply “steps”.

Step-type escalators are useful when the vertical distance is too great for conventional elevators and people movers to be practical, such as in department stores and shopping malls. They may also be used in mid-rise buildings where elevators would take up too much space or require an excessive number of elevator shafts.

The most common application of stepped conveyors is the descending type, but some designs also exist for ascending motion. In descending applications, the direction of travel is usually controlled by permanent rules (e.g., you always go down on the left), but some designs allow unidirectional travel with no restrictions on direction (e.g., you can go either way at any given time).

Step-type escalators typically have one or two steps per tread, depending on the desired capacity, but other configurations are possible (e.g., three steps per tread). The number of steps per tread can range from 1 to 5 or more; however, this will ultimately depend on the total length of each step and the maximum possible speed of the escalator. A single-step-type escalator can transport up to 1,500 passengers per hour in a single direction at a rate of 3 feet per second; however, this number will vary depending on the length and configuration of each step.

Crisscross Escalator

Crisscross escalators are a relatively new type of escalator that is becoming increasingly popular in cities worldwide. These escalators have two moving walkways crisscross each other at 90° angles and in opposite directions, allowing passengers to move between floors quickly.

Crisscross escalators are most commonly used in transit stations, shopping malls, airports and other places where many people need to get from one floor to another quickly and efficiently. They are also used in stadiums to transport spectators up and down to their seats during sporting events.

History of The Crisscross Escalator

Crisscross Otis Elevator Company first developed escalators in 1992 to improve efficiency while providing easy access for everyone. The idea was that if two moving walkways crossed each other at 90° angles, they would help people move between floors without having to worry about getting stuck behind someone who couldn’t keep up with their own pace or following crowd flow patterns that tend to form on traditional straight escalators.

The first crisscross escalator was installed at Frankfurt Airport in Germany in 2000 and since then has become one of the most popular types of escalator on the market today.

Multi-Story Escalators

The first multi-story escalator was installed in London’s Harrods department store in 1911. It was designed by British engineer Jesse W. Reno and built by the Otis Elevator Company.

Multi-story escalators are designed to move people through a building or facility whose floors are too far apart to be connected by standard escalators. Multi-story escalators can be used in buildings of any height and installed indoors or outdoors.

Multi-story escalators are also known as vertical transportation systems, vertical lifts, and vertical conveyors. Many multi-story escalators are used in transit centres and airports where passengers must walk long distances between gates and baggage claim areas. Others are found in office buildings and retail stores.

Multi-story escalators use a series of steps that move up or down along a track system, much like the standard escalator. Each step has an individual motor that moves along its track, allowing each step to move independently from the others. The steps are often arranged in pairs with an incline similar to a staircase so that users don’t feel like they’re walking straight up or down when using them.

Outdoor Escalators

The outdoor step escalator is a type of escalator installed outdoors; It is designed to be outside in the elements. This means they are made with materials that will not break down or wear out easily when exposed to the sun, rain, snow and other elements. They are also made with materials that can withstand any weather without being damaged by them. It is also called an outdoor escalator, outdoor moving staircase, or simply moving stairs.

Outdoor escalators are a great way to move people quickly and efficiently through large spaces. They can be used in all kinds of places, from airports, shopping malls, train stations, stadiums, and other sports arenas.

Escalator Application

Escalators are widely used in various industries because of their convenience and high efficiency, including:

- Subway and railway station

- Airport

- Shopping mall

- Supermarket

- Hospital

- Tourist attraction

Principle of Escalator

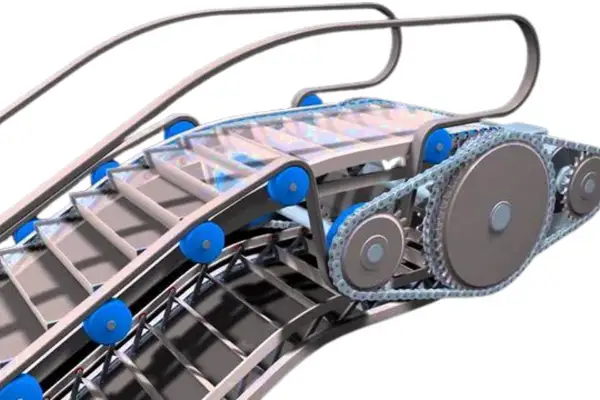

The main drive unit is the power source of the escalator, which transmits the power to the main shaft drive axis through the main drive chain. The main drive axis drives the step chain to drive the steps for upward or downward movement; the step chain tensioning device installed in the lower part plays the role of tensioning the step chain.

Structure of Escalator

Escalator is large and complex transportation equipment with a mechanical structure as the main body, which is divided into 8 parts according to the function: supporting structure (truss), step system, guide rail system, handrail belt system, handrail device, safety protection device, electrical control system and automatic lubrication device.

Handrail Device

The extension part above the escalator steps includes an apron plate, a guard plate, a cover plate and a mobile handrail belt. Among them, the mobile handrail belt is located on the top surface of the handrail device, which runs synchronously with the stairs and is a belt-like part for passengers to hold.

The guard plate is the main plate part of the handrail device, located below the mobile handrail belt, made of glass. The cover plate is the decorative cover of the escalator handrail unit extending in the running direction. The apron plate is the lowest wall plate in the handrail device, located under the inner cover plate, adjacent to the stairs and has a small gap.

Truss

The steel structure assembly supports the weight and load of the escalator with control panels, drive units for the steps and moving handrail belts, and other components housed inside the structure.

Control panel: controls stop/start operation and supplies power to the drive unit.

Drive unit for escalators: contains motors, reducers, electromagnetic brakes, V-belts, sprockets and other components.

Drive chain: The chain transmits the driving force from the drive unit to the drive sheaves (sprockets).

Drive wheel mounting: at the top and bottom to drive the steps. The top sprocket drives the moving rungs, and the bottom sprocket turns the rungs.

Main rail: The guide rail for the main wheel to guide.

Auxiliary rails: guide rails for the auxiliary wheels.

Mobile handrail drive unit: a device that drives the mobile handrail indirectly through the mobile handrail drive chain at the same speed as the steps.

Advantages of Escalators

- Continuously ride a large number of people performance, and thus suitable for large public buildings with this kind of people flow characteristics, such as large shopping malls, etc.,

- It can be arranged upward or downward separately and also arranged upward and downward side by side.

- No need to set up a machine room on the top of the building and consider a buffer pit on the ground floor, so it takes up less space than the elevator.

- In case of failure, escalators can be used as general stairs, unlike elevators, which have the weakness of interrupting use in case of failure.

Disadvantages of Escalator

1. Slow speed.

2. It is also inconvenient for old and frail people who carry large items. Therefore, while installing escalators in public buildings, it is still necessary to consider installing elevators or general stairs as auxiliary vertical transportation.

Escalator Operation Method

Starting Method

(1) Start the escalator with the key “switch” and take out the key in the middle position.

2)Start the “buzzer” with the key.

3)If everything is normal, start the escalator with the lock key and keep this position for 0.5~1.0 seconds, then take out the lock key.

Stop

(1) Make sure there are no passengers on the escalator.

2)Start the “buzzer” with the key.

(3) Close the escalator with the key.

(4) Use the key to turn off the “switch” and remove the key in the middle position.

Temporary Change of Direction

Stop the escalator first. Please do not change the direction of operation before the escalator is completely stopped. Otherwise, its mechanical structure will be damaged. Escalators in the direction of operation for up to 3 months should make the escalator change the direction of operation.

How Does An Escalator Work?

Escalators consist of two sets of conveyors. One group is the chain drive, a series of steps dragged by a ladder chain; this part forms the part of the elevator for us to walk on. The other group is the handrail belt, which consists of conveyor tape. A unified drive shaft drives the two conveyor belts to maintain a uniform line speed.

In addition to the two key conveyor belts, the entire escalator is a giant metal frame within which all the components are mounted. At the ends of the escalator, there will be a vast space with a cover for pedestrians to pass through. Maintenance personnel can open this cover to enter the interior of the escalator for maintenance.

Haven’t you found the right type of escalator yet? Contact Dazen for professional advice.